Without effective stock control, companies risk issues such as overstocking, which can lead to increased operational expenses and dissatisfied customers. To address these challenges, organizations adopt various stock control methods, supported by modern inventory management software that automates tracking. By combining structured processes with technology-driven solutions, businesses can streamline operations across the logistics chain.

What is Stock Control?

Stock control is the systematic process of managing, monitoring, and optimizing the movement of goods within a supply chain. It ensures that the correct quantity of products is available at the right time, minimizing the risks of stockouts and overstocking.

In practice, stock control involves a range of activities, including demand forecasting, reorder level management, safety stock calculation, and real-time inventory tracking. By implementing structured stock control procedures, logistics managers can enhance overall supply chain performance.

Popular Stock Control Methods

Just-in-Time (JIT)

Just-in-Time (JIT) inventory management is a lean strategy in which stock is replenished only as needed for production or customer demand. By minimizing excess inventory, companies reduce carrying costs, storage needs, and risk of obsolescence. However, JIT requires a highly responsive supply chain and strong collaboration with suppliers to avoid stockouts.

Just-in-Case (JIC)

In contrast to JIT, Just-in-Case (JIC) emphasizes maintaining buffer stock to safeguard against demand surges or supply disruptions. This approach provides higher service reliability, especially in industries prone to unpredictable lead times or seasonal fluctuations.

While JIC reduces the risk of stockouts, it can increase storage and obsolescence costs, making it less efficient for fast-moving or perishable goods. Companies often adopt JIC when operating in volatile markets where supply chain resilience takes precedence over cost efficiency.

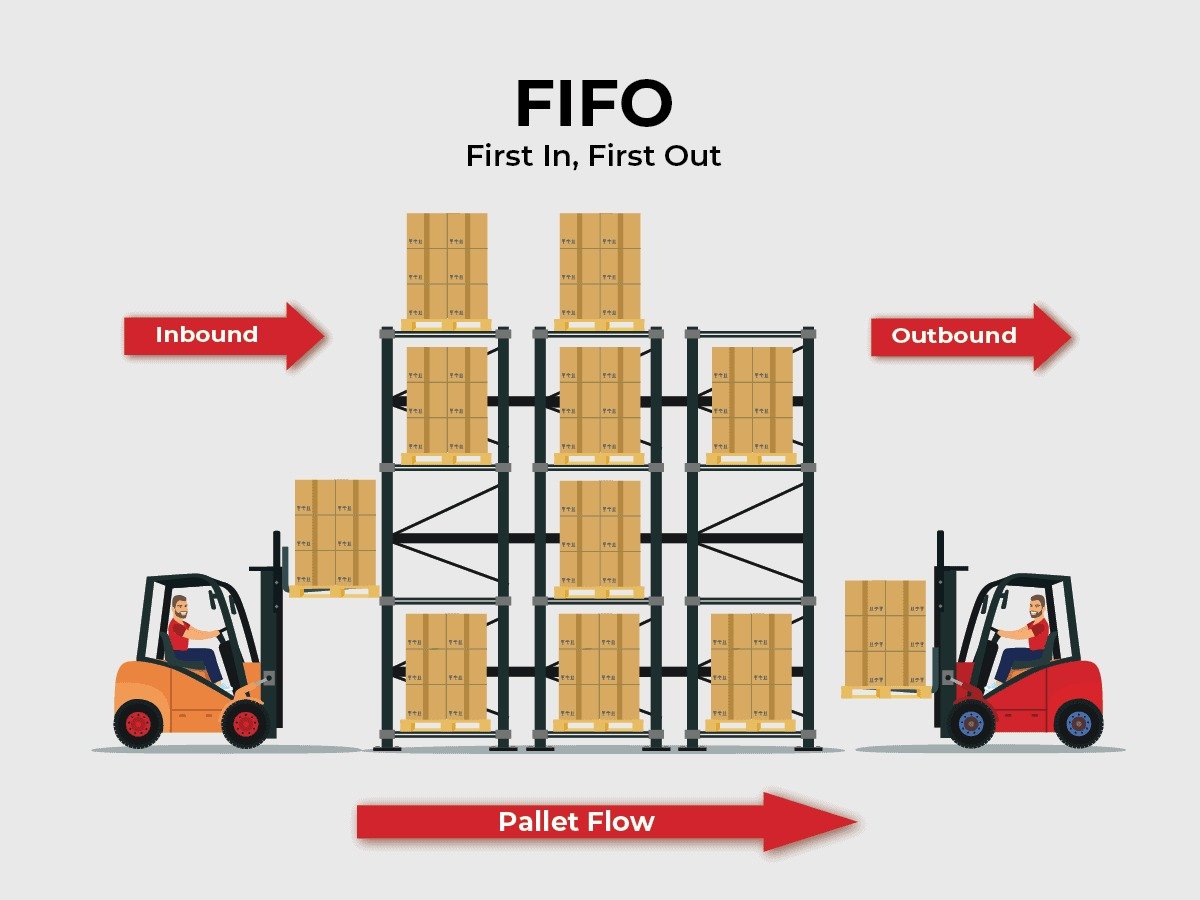

First In, First Out (FIFO)

The First In, First Out (FIFO) method ensures that the earliest received stock is dispatched first. This technique is critical in industries where products have expiration dates—such as food, pharmaceuticals, and chemicals, which help to maintain compliance with quality and safety regulations.

Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is a classical inventory model that determines the optimal order size to minimize the total cost of procurement, carrying, and stockouts. By calculating EOQ, firms balance the trade-off between ordering frequency and storage expense. While highly effective for stable demand patterns, EOQ may require adjustments for businesses dealing with fluctuating lead times, dynamic pricing, or sudden demand shifts.

Vendor-Managed Inventory (VMI)

Vendor-Managed Inventory (VMI) shifts responsibility for stock replenishment from the buyer to the supplier. Under this model, suppliers monitor the buyer’s inventory levels and autonomously decide when to replenish stock. This reduces administrative workload for the buyer and fosters closer collaboration across the supply chain.

Logistics teams benefit from VMI, as it enhances supply visibility and streamlines transportation planning by aligning deliveries with supplier logistics networks. However, it requires high levels of trust, accurate data sharing, and sophisticated IT integration between trading partners to ensure alignment of objectives and service performance.

Batch Tracking and Control

Batch tracking is the process of monitoring products through production and distribution in defined lots or batches. This method is significant for industries where traceability, quality control, and regulatory compliance are critical.

From a logistics standpoint, batch control enhances visibility, enabling rapid recalls, quality audits, and compliance reporting. It also allows firms to identify inefficiencies in their production or supply chains, thereby improving their long-term operational resilience.

Stock Control Systems

Stock control systems provide visibility across the supply chain, enabling businesses to track stock levels in real-time, identify discrepancies, and prevent issues such as overstocking or stockouts. From a logistics perspective, stock control is crucial for maintaining service levels while minimizing the carrying costs of inventory.

There are various methods of stock control, each suited to different operational contexts. For example, the First-In, First-Out (FIFO) approach helps prevent obsolescence in perishable goods. At the same time, the Just-In-Time (JIT) system reduces holding costs by synchronizing replenishment with production or customer orders.

In practice, many organizations adopt a hybrid approach that combines methods to strike a balance between efficiency, risk mitigation, and customer satisfaction. By applying the right system, companies can align their inventory policies with their overall logistics strategy and enhance supply chain performance.

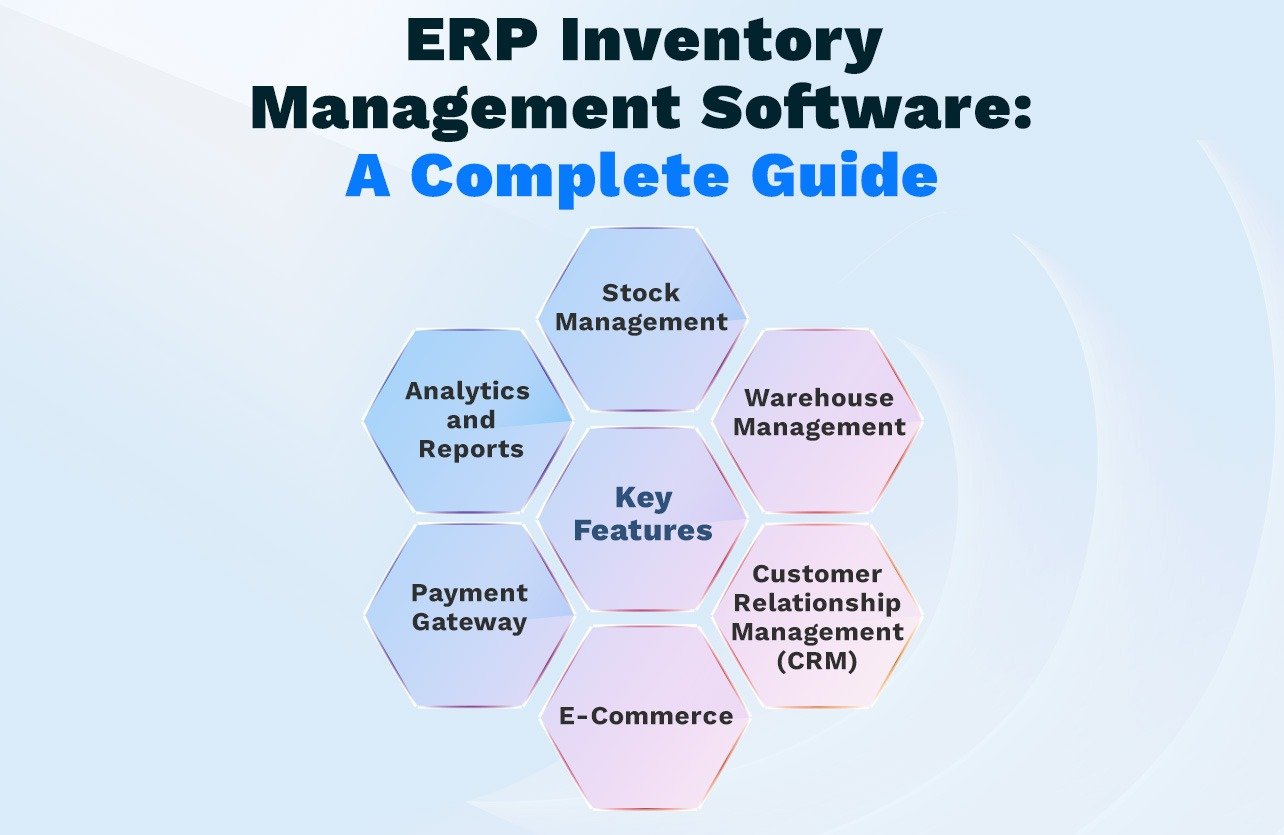

Stock Management Software

Stock management software serves as a digital solution to streamline and automate the complex process of controlling inventory. These platforms integrate data from procurement, warehousing, and distribution to provide a centralized view of stock levels and movement.

Modern software often includes advanced functionalities such as barcode scanning, RFID tracking, and real-time reporting dashboards,… which empower decision-makers to act quickly in dynamic supply chain environments. Furthermore, integration with transportation management systems (TMS) and enterprise resource planning (ERP) platforms ensures that stock data aligns seamlessly with order processing and shipment tracking.

How the Stock Ordering Process Works

Use one standardized inventory control method

Businesses can choose from established frameworks such as First-In-First-Out (FIFO), Just-in-Time (JIT), or Economic Order Quantity (EOQ), depending on their operational model. By committing to one method, companies can streamline procurement decisions and maintain traceability throughout the supply chain.

The choice of method should also align with the nature of the product (often demand FIFO), while high-value industrial components may benefit from JIT replenishment. A single, consistent system creates predictability, which is essential for both suppliers and customers.

Assess your current stock situation

Before placing new orders, businesses must conduct a thorough assessment of their existing inventory. This involves evaluating stock on hand, analyzing turnover rates, and identifying slow-moving or obsolete items. Using metrics such as Days of Inventory on Hand (DOH) or Inventory Turnover Ratio allows companies to understand the velocity at which products flow through the warehouse.

This diagnostic step prevents overstocking and uncovers inefficiencies. For example, identifying surplus safety stock or seasonally obsolete goods can inform better purchasing decisions and free up valuable storage capacity. The result is a data-driven baseline that strengthens demand forecasting and order accuracy.

Define the optimal stock levels for your business

Optimal stock levels strike the balance between supply availability and cost efficiency. Setting these levels requires analyzing demand variability, supplier lead times, and service-level expectations to ensure optimal performance. Establishing parameters such as reorder points (ROP), safety stock thresholds, and maximum stock levels helps ensure that critical items remain available without tying up excessive capital.

To define these levels accurately, companies often integrate historical sales data with predictive analytics to inform their decisions. This not only supports continuity of operations but also minimizes risks of stockouts and backorders.

Continuously monitor and improve inventory practices

Businesses should employ regular cycle counts, real-time inventory tracking systems, and periodic audits to verify the accuracy of their data. Performance metrics such as order fulfillment rate, carrying cost percentage, and stockout frequency serve as benchmarks to guide improvements.

Additionally, adopting automation tools—such as warehouse management systems (WMS) or AI-driven demand forecasting—enables more agile and precise adjustments to inventory strategies. Continuous monitoring ensures that the ordering process evolves in response to market dynamics, supplier reliability, and customer expectations, ultimately reinforcing supply chain resilience.

In conclusion, stock control is a vital function that ensures businesses maintain the right balance between supply and demand, minimizing both excess inventory and stock shortages. By applying structured methods, supported by reliable management software, organizations can streamline their inventory processes and gain real-time visibility across the supply chain.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)