In the current era of e-commerce and supply chain development, it’s essential to develop specialized types of warehouses to meet the unique needs of businesses. High-Bay Warehouses are one such example. In the following sections, we will explore the advantages of high-bay warehouses, how they work, look at their industry applications, and compare them to conventional warehouses.

What is a High-Bay Warehouse?

A high-bay warehouse, also known as an HRL (short for Hochregallager in German, meaning high-rack warehouse), is a special facility that has a height from 12 meters and can be up to 50 meters high. This is in contrast to a regular warehouse, which is generally lower than 10 meters.

In these warehouses, items are placed on pallets and stacked on the tall shelves. These shelves are designed to be operated by special machines known as Storage and Retrieval Machines (SRMs). These machines can be controlled automatically or by a person, and they can lift and lower the pallets to the correct height.

Key Advantages of High-Bay Warehouses

High-bay warehouses can maximize vertical storage space, which helps to increase storage density and make the best use of both floor area and overall building volume. For these reasons, high-bay warehouses offer many benefits, including:

- Space Optimization: Built up to 50 meters high, they allow you to store a massive volume of goods on a small piece of land, which is ideal where real estate is expensive

- Efficiency and Automation: Automated systems like AS/RS move items faster than humans, enabling continuous, 24/7 operations and a more efficient supply chain.

- Reduced Costs: Automation lowers the need for a large workforce and minimizes errors, saving money over time.

- Improved Inventory Control: Advanced software tracks every item in real-time, providing an accurate view of inventory and reducing misplaced products.

- Enhanced Safety: Machines handle dangerous tasks, such as lifting heavy pallets, which reduces the risk of accidents and creates a safer work environment for people.

High-Bay Warehouse Automation Explained

High-bay warehouses are made to be very efficient using advanced technology. Instead of relying on human workers to move every item, they use a range of automated systems to handle goods quickly and precisely. These implementations of automation are a core element to their success.

Handling Hundreds of Thousands of Pallets

One of the automation features of a high-bay warehouse is its ability to manage a large number of pallets. They use special software to keep track of every single item, so the system always knows the exact location of all goods in real-time. This digital tracking is key for processing a high volume of goods with precision.

Automated Storage and Retrieval (AS/RS)

An Automated Storage and Retrieval System (AS/RS) is the core of a high-bay warehouse. It is a technology-driven system that uses automated cranes, conveyors, shuttles, or other robotic systems to put products away and get them back from their exact locations.

These systems are designed to handle different types and volumes of inventory, from single items to entire pallets, at various speeds. By replacing traditional shelving, AS/RS helps companies save floor space, improve safety for workers, and increase overall productivity by automating the most time-consuming tasks.

Maximum Load Capacity

High-bay warehouses are built with extremely strong structures that can handle very heavy loads. The racking systems and automated machines are specifically designed to support a significant amount of weight, much more than a traditional warehouse. This allows companies to store a wide variety of products, from lightweight items to heavy industrial goods, all within the same system.

Operations in Extreme Environments

Another benefit of automation is that these warehouses can work in conditions that are difficult or unsafe for humans. For example, some high-bay warehouses are built as deep-freeze cold storage, where temperatures are too low for humans to work. They can also be used for storing pharmaceuticals under strict environmental control or for handling high-risk goods. The automated systems can operate 24/7 in these challenging environments without any problems, which is impossible for human workers to do.

High-Bay Warehouse: How does it work?

In an automated high-bay warehouse, the entire operation is controlled by a Warehouse Management System (WMS). This intelligent software directs all the movements of goods and automated equipment.

When goods arrive, they are placed onto a conveyor system. The WMS then determines the optimal storage location for the items and assigns a stacker crane to transport the pallet to that exact spot.

These cranes operate continuously, handling loads up to 50 meters high. This process functions on a “goods-to-person” principle, which means the system brings the item directly to the employee, eliminating the need for workers to walk around searching for products.

Beyond just movement, the WMS also provides real-time inventory control. It can be programmed to manage all data, from product expiration dates to customer orders, providing comprehensive oversight and ensuring accuracy across the entire operation.

Industry Applications of High-Bay Warehouses

High-bay warehouses play a great role across multiple industries thanks to their ability to maximize vertical storage space, automate processes, and support efficient, high-density inventory management:

- Automotive: Optimize raw material and spare parts storage to streamline production.

- Pharmaceuticals: Ensure strict precision, quality assurance, and controlled storage for sensitive items.

- Food & Beverages: Meet cooling requirements and maintain high hygiene standards.

- E-commerce: Enable fast storage and retrieval to handle large volumes of online orders efficiently.

- Retail: Support DIY stores, hypermarkets, and furniture centers in managing vast inventories.

- General Manufacturing: Enhance production flexibility by efficiently storing and handling packaged goods on pallets.

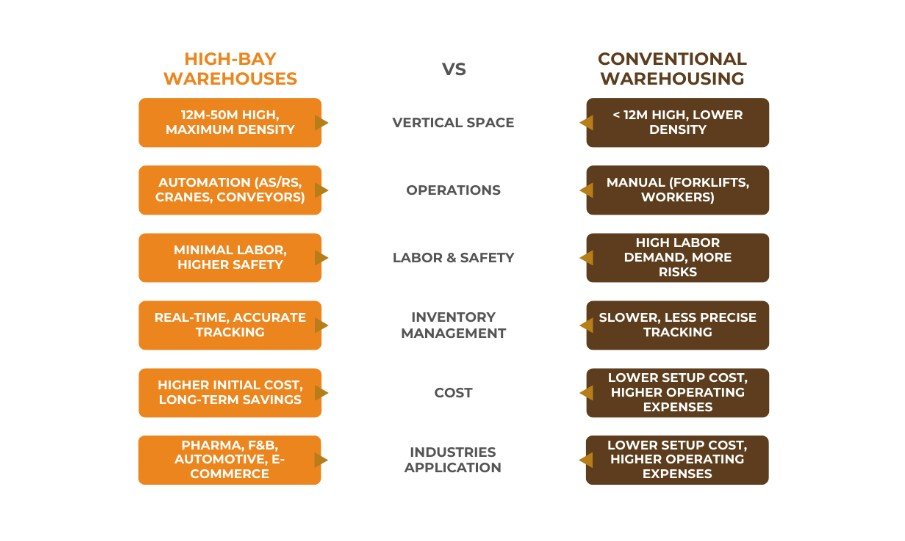

High-Bay Warehouses vs Conventional Warehousing

When choosing the right storage solution, it’s important to understand the key differences between high-bay warehouses and conventional warehousing. Here are some of the most important distinctions to consider:

High-Bay Warehouses

- Vertical Optimization: Utilize heights of 12 meters – 50 meters for maximum storage density.

- Automation-Driven: Rely on AS/RS, stacker cranes, and conveyors to streamline operations.

- Labor Efficiency & Safety: Minimize human involvement in storage/retrieval, reducing risks.

- Real-Time Accuracy: Enable precise, automated inventory tracking and management.

- Long-Term Cost Advantage: Higher upfront investment but greater efficiency and savings over time.

- Industry Suitability: Ideal for pharmaceuticals, food & beverages, automotive, and e-commerce.

Conventional Warehousing

- Limited Height Utilization: Typically below 12 meters, resulting in lower storage density.

- Manual Operations: Depend on forklifts and workers for handling goods.

- High Labor Dependency: Increased workforce needs with greater risk of errors.

- Slower Tracking: Inventory management is often less precise and less efficient.

- Lower Initial Cost: More affordable to set up but costly in long-term operations.

- Flexible for Small Scale: Better suited for small businesses or low-volume storage needs.

To summarize, High-Bay Warehouses are more than storage facilities, they are strategic assets that help businesses scale faster, operate smarter, and stay competitive. By maximizing vertical space, integrating automation, and enabling real-time inventory visibility, they provide a strong foundation for efficient supply chains and sustainable growth.

At Keys Logistics, we bring that advantage to life with smart warehousing, fulfillment, and end-to-end logistics solutions across the U.S., UK, and Europe. With our proven expertise and 99.9% on-time fulfillment, we help e-commerce brands scale faster, operate smarter, and deliver better. Contact us today, and our experts will provide the right logistics solutions tailored to your business.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)