Cross-docking reduces handling time, accelerates delivery schedules, and often results in significant cost savings. However, while the model presents clear advantages in efficiency and responsiveness, it also comes with challenges that organizations must address to ensure smooth execution. Understanding the different types of cross-docking enables businesses to determine whether this method is the right fit for their logistics network.

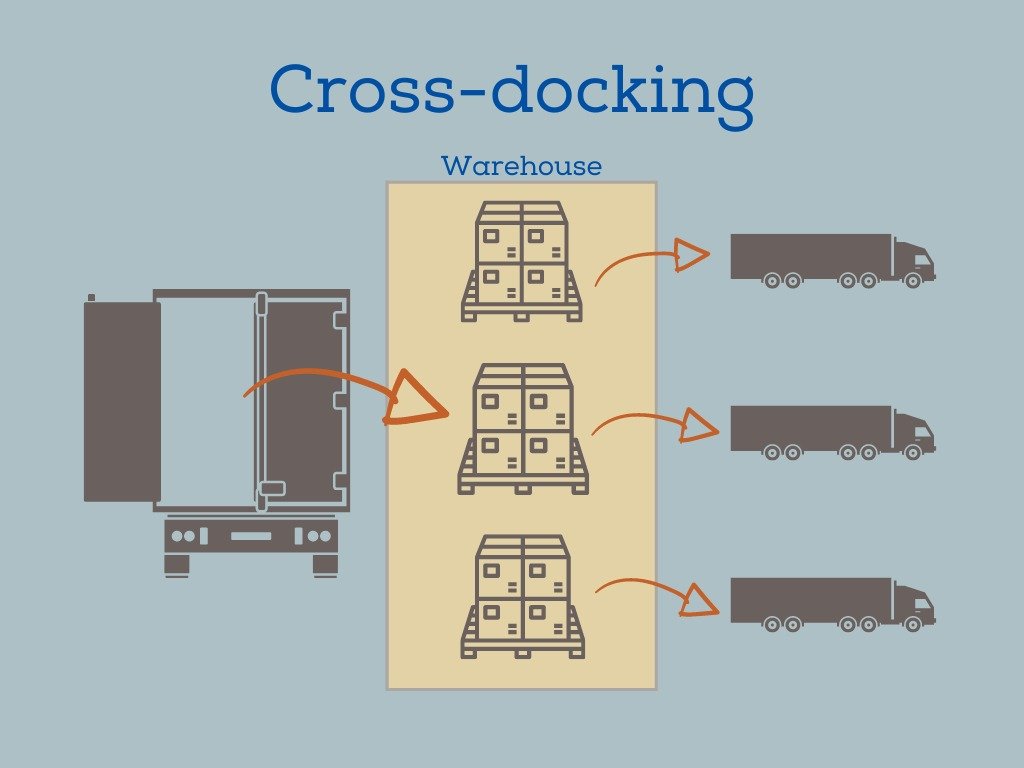

What Is Cross-Docking?

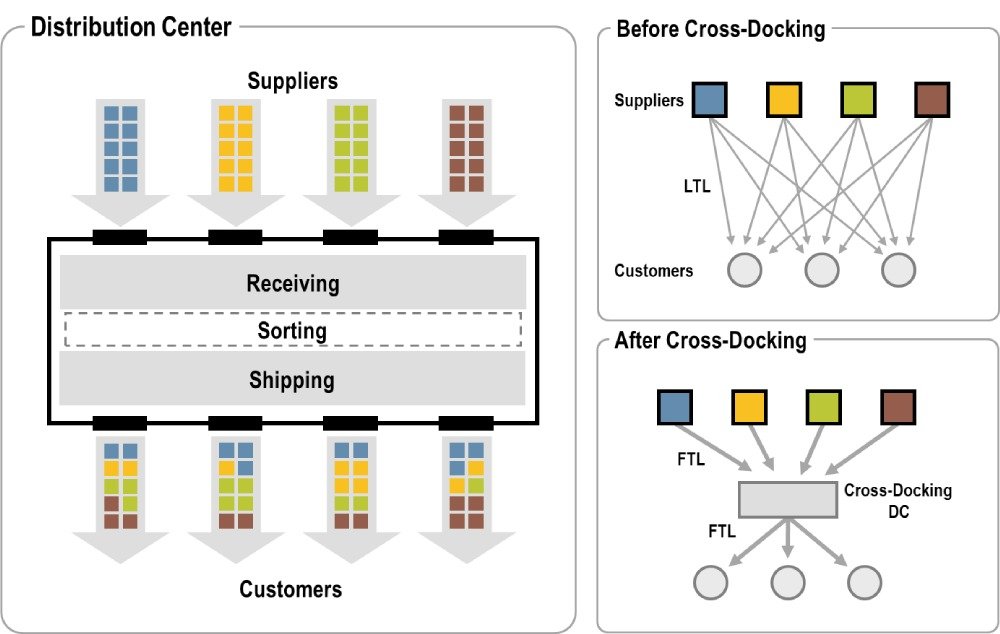

Cross-docking is a streamlined logistics strategy in which inbound goods are unloaded directly from one mode of transportation and transferred onto outbound vehicles with minimal storage time in between. Instead of being held in a warehouse, products move almost immediately through a distribution facility, minimizing inventory holding costs and accelerating order fulfillment.

Types of Cross-Docking

Pre-distribution cross-docking

Pre-distribution cross-docking involves sorting and allocating goods at the distribution center before they are shipped directly to the end customer or retail outlet. The distribution facility essentially acts as a transient sorting hub, ensuring that each outbound shipment is tailored to a specific customer’s requirements.

This method is particularly effective for fast-moving consumer goods (FMCG), perishable products, or just-in-time (JIT) deliveries where minimizing handling time is crucial. By eliminating unnecessary storage and secondary handling, pre-distribution cross-docking reduces dwell time and lowers inventory carrying costs. However, it requires accurate demand forecasting and robust information systems to synchronize inbound and outbound flows seamlessly.

Consolidation cross-docking

Consolidation cross-docking focuses on combining shipments from multiple suppliers or manufacturing sites into a single, more cost-effective outbound load. Unlike pre-distribution, consolidation typically involves temporary staging of goods at the cross-dock facility until sufficient volumes are accumulated for dispatch.

This approach is widely used in industries with fragmented supply bases, such as automotive parts distribution, retail replenishment, or e-commerce fulfillment. Benefits include lower transportation costs, reduced carbon footprint, and improved supply chain efficiency. However, it requires precise scheduling and supplier coordination to avoid congestion at the cross-dock terminal.

Hybrid cross-docking

Hybrid cross-docking is a flexible model that combines elements of both pre-distribution and consolidation. In practice, some products may be sorted and routed directly to customers (pre-distribution), while others are temporarily staged until consolidated with additional loads (consolidation). This dual approach allows organizations to adapt to varying demand patterns, product characteristics, and shipping priorities.

Benefits of Cross-Docking

Cross-docking helps organizations achieve faster turnaround and improved responsiveness to market demand. Key benefits of cross-docking include:

- Reduced inventory costs: Eliminates the need for long-term warehousing, lowering carrying costs and capital tied up in stock.

- Faster order fulfillment: Goods move directly through distribution centers, accelerating delivery lead times.

- Improved supply chain efficiency: Streamlines material handling and reduces unnecessary touchpoints, which cuts labor and handling expenses.

- Enhanced transportation utilization: Consolidates shipments to maximize truckload efficiency and decrease transportation costs.

- Stronger customer satisfaction: Ensures timely and reliable deliveries, a crucial factor for just-in-time operations and high-demand markets.

Challenges of Cross-Docking

While cross-docking offers significant advantages, it also comes with operational complexities that can hinder efficiency if not properly managed. Common challenges include:

- High initial investment: Requires modern facilities, dock infrastructure, and advanced warehouse management systems (WMS).

- Complex coordination: Relies on exact scheduling between suppliers, carriers, and distribution centers to avoid congestion or idle time.

- Limited product suitability: Works best for high-volume, fast-moving goods; not ideal for low-demand or fragile products requiring special handling.

- Dependency on technology: Requires robust real-time tracking and data integration to manage inbound and outbound transfers seamlessly.p’

- Risk of service disruptions: Weather, traffic, or supplier delays can significantly impact performance since there is no buffer stock.

Cross-Docking Process: How it work?

The cross-docking process includes the following stages:

- Inbound Transportation – Products arrive at the cross-dock terminal from manufacturers or suppliers.

- Unloading and Receiving – Goods are unloaded, scanned, and checked for accuracy and quality.

- Sorting and Allocation – Items are quickly classified and assigned to the appropriate outbound dock based on final destinations.

- Consolidation – Shipments are combined where possible to optimize outbound loads and reduce transportation costs.

- Outbound Loading – Products are immediately reloaded onto outbound vehicles for distribution to retailers, wholesalers, or end customers.

Cross-Docking Best Practices

Warehouse Shape

The physical layout of a warehouse has a direct impact on cross-docking efficiency. A rectangular or “I-shaped” facility is often preferred because it supports straight-line product flows, reducing unnecessary material handling. This minimizes travel distance between inbound and outbound areas, which not only accelerates throughput but also lowers labor costs. In contrast, irregular or “U-shaped” layouts can cause congestion, misrouting, and excess handling, all of which compromise the time-sensitive nature of cross-docking.

When designing a warehouse, logistics planners should prioritize clear sightlines, unobstructed movement paths, and sufficient staging zones adjacent to both inbound and outbound docks. A streamlined shape reduces dwell time, enabling freight to move seamlessly from receiving to shipping without long-term storage.

Number and Placement of Dock Doors

The number and strategic placement of dock doors are critical for balancing inbound and outbound traffic in a cross-dock operation. Too few doors create bottlenecks, while excessive doors add construction and maintenance costs without improving flow. The optimal ratio depends on shipment volume, SKU variety, and carrier scheduling. As a general guideline, facilities should provide separate clusters of doors for inbound and outbound activities, minimizing cross-traffic between receiving and shipping functions.

Inbound and Outbound Shipments Schedule

Effective cross-docking requires precise coordination between inbound arrivals and outbound dispatches. Planners should maintain a tightly managed appointment system, ensuring inbound trucks arrive just in time for outbound loading. This minimizes storage requirements and optimizes vehicle turnaround.

To achieve this, logistics managers can adopt scheduling practices such as:

- Time-slot allocation: Assigning carriers specific windows for delivery and pick-up.

- Priority sequencing: Aligning inbound unloading order with outbound shipping deadlines.

- Dynamic rescheduling: Using real-time tracking and TMS (Transportation Management Systems) to adjust dock activity as conditions change.

By synchronizing schedules with precision, cross-dock facilities can achieve higher velocity, reduce demurrage costs, and increase customer satisfaction through on-time delivery performance.

Cross-Docking Explained

Pre-Distribution vs. Post-Distribution Cross-Docking

Pre-distribution cross-docking occurs when goods arrive at a facility already labeled, sorted, and assigned to specific outbound destinations. Here, the distribution center primarily serves as a transfer point, minimizing on-site processing and decision-making. This method is advantageous for high-volume, standardized goods, such as packaged food or consumer electronics, where demand forecasts and order allocations are predetermined.

Post-distribution cross-docking, by contrast, involves holding goods temporarily at the dock until allocation decisions are made based on real-time demand or updated order information. This method is particularly valuable in volatile demand environments, such as those in seasonal fashion or promotional campaigns.

Dropshipping vs. Cross-Docking

Dropshipping bypasses the intermediary distribution center entirely; manufacturers or wholesalers ship directly to the end customer upon receipt of the order. This reduces handling but requires suppliers to manage last-mile delivery performance.

Cross-docking, however, retains a central coordination point. By consolidating goods at a cross-dock facility, companies can achieve transportation economies of scale, and maintain greater visibility over outbound flows.

In essence, dropshipping prioritizes supplier-driven efficiency, while cross-docking balances customer service with transportation cost optimization. For businesses managing multiple SKUs across dispersed markets, cross-docking often provides a more controlled and scalable solution.

Direct Shipment vs. Cross-Docking

Direct shipment refers to the movement of goods from supplier to customer without intermediary stops, typically in full truckload (FTL) or large-volume scenarios. It is cost-effective when demand is concentrated and predictable, as it reduces handling and minimizes potential for cargo damage. However, it is less efficient when demand is fragmented across multiple destinations.

Cross-docking offers a middle ground by consolidating inbound goods from multiple suppliers and redistributing them efficiently to diverse outbound channels. This not only maximizes truckload utilization but also shortens replenishment cycles for retailers and distributors. While direct shipment excels in simplicity, cross-docking adds strategic flexibility, allowing logistics managers to match supply more dynamically to demand while still controlling the cost per unit delivered.

In conclusion, cross-docking stands as a strategic logistics practice that can significantly streamline supply chain operations when applied correctly. By minimizing storage time, businesses can reduce handling costs, optimize inventory management, and enhance customer responsiveness.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)