When evaluating logistics strategies, businesses often face the choice between cross docking and traditional warehousing. Each model represents a distinct approach to inventory management and distribution. By comparing these two methods, organizations can better understand which system aligns with their supply chain goals, operational capacity, and customer service requirements.

What Is Cross Docking?

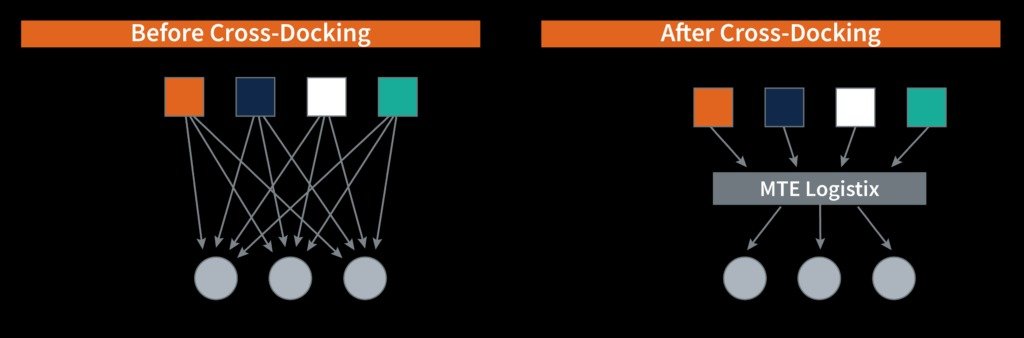

Cross-docking is a lean logistics strategy where inbound shipments are directly transferred to outbound vehicles with minimal or no storage in between. This approach minimizes inventory holding costs and accelerates order fulfillment, making it particularly valuable in supply chains where speed and responsiveness are critical.

Types of Cross Docking?

The two primary types of cross-docking are pre-distribution and post-distribution:

- Pre-distribution cross-docking involves sorting products at the receiving dock according to predetermined customer orders or retail destinations. Goods are directly routed to outbound transportation without further handling. This model requires highly accurate demand forecasts and advanced information systems to ensure correct allocation before arrival.

- Post-distribution cross-docking holds goods at the dock or a short-term staging area until final customer orders or destination details are confirmed. While slightly slower, it provides flexibility, reduces the risk of misallocation, and is well-suited for dynamic or demand-driven environments such as fashion retail or promotional campaigns.

Benefits of Cross Docking?

Cross-docking delivers a strategic advantages across supply chains:

- Faster delivery: By bypassing long-term storage, goods reach end customers more quickly, improving lead times.

- Lower costs: Reduces warehousing expenses, minimizes labor associated with put-away and retrieval, and cuts transportation costs through load consolidation.

- Improved inventory management: Reduces on-hand stock levels and supports lean inventory practices.

- Reduced product damage: Fewer handling stages lower the risk of breakage or spoilage.

- Increased supply chain efficiency: Streamlined flow enhances coordination between suppliers, distributors and retailers.

- Enhanced customer satisfaction: Faster, more reliable deliveries strengthen service levels and brand loyalty.

- Environmental benefits: The reduction in storage facilities and optimized transportation routes leads to lower energy consumption and reduced emissions.

Why Cross-Docking Is Needed

Globalized trade and e-commerce growth have shortened customer tolerance for delays, making rapid fulfillment a competitive necessity. Cross-docking directly addresses this need by accelerating the flow of goods and supporting next-day or even same-day delivery models.

Additionally, organizations face rising warehousing costs, fluctuating demand, and sustainability pressures. By reducing storage dependency and optimizing transportation, cross-docking not only lowers operating expenses but also minimizes the environmental footprint of logistics operations. In sectors such as retail, pharmaceuticals, and perishables, where shelf life and service quality are critical, cross-docking provides a structural advantage in meeting both operational efficiency and customer expectations.

What Is Traditional Warehousing?

Traditional warehousing is a storage model where goods are received, cataloged, and stored in a fixed facility until they are required for distribution. In this setup, inventory is typically held in bulk, organized by SKU, and managed through standardized storage systems, such as pallet racking or shelving. The primary objective of this model is to ensure product availability, minimize stockouts, and create a buffer against fluctuations in supply and demand.

Cross Docking vs Traditional Warehousing: Key Differences

Below is a comparative table outlining the primary distinctions between cross-docking and traditional warehousing:

| Criteria | Cross-Docking | Traditional Warehousing |

| Inventory Holding | Minimal to none; goods are transferred directly to outbound transportation. | Goods are stored for days, weeks, or months depending on demand and order cycles. |

| Handling Process | Focus on rapid sorting, consolidation, and dispatch. | Involves put-away, storage, picking, packing, and shipping activities. |

| Lead Time | Significantly shorter, supporting just-in-time (JIT) distribution. | Longer due to storage and retrieval processes. |

| Operational Cost | Lower storage costs but higher coordination and scheduling requirements. | Higher storage and labor costs due to ongoing inventory management. |

| Risk Exposure | Reduced risk of obsolescence or excess inventory. | Higher risk of overstocking, product damage, and holding costs. |

| Best Use Cases | High-velocity goods, perishable products, or time-sensitive shipments. | Slow-moving items, seasonal inventory, or products requiring value-added warehousing. |

Cross Docking vs Traditional Warehousing: The Right Choice for Your Business?

Traditional warehousing relies on storing inventory for extended periods, offering greater flexibility in the face of demand fluctuations and safeguarding against supply chain disruptions. However, this approach incurs higher storage costs, longer lead times, and increased handling, which may not suit industries requiring rapid fulfillment or lean inventory control.

On the other hand, cross-docking minimizes storage by transferring goods directly from inbound to outbound transportation. This strategy significantly reduces inventory holding costs, accelerates delivery cycles, and improves overall efficiency. However, it requires precise demand forecasting, robust supplier coordination, and advanced transportation scheduling to avoid stockouts or service failures.

Choosing between the two depends on a company’s product characteristics, demand variability, and distribution priorities. For high-velocity goods and just-in-time supply chains, cross-docking offers substantial advantages. In contrast, traditional warehousing remains better suited for businesses managing seasonal demand, safety stock, or long-tail products.

The comparison between cross-docking and traditional warehousing highlights two distinct approaches to supply chain management, each offering unique advantages and limitations. Ultimately, the decision between these models depends on a company’s operational priorities, product characteristics, and customer service requirements. By carefully evaluating these factors, businesses can select the most suitable strategy to strengthen their logistics performance and competitive edge.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)