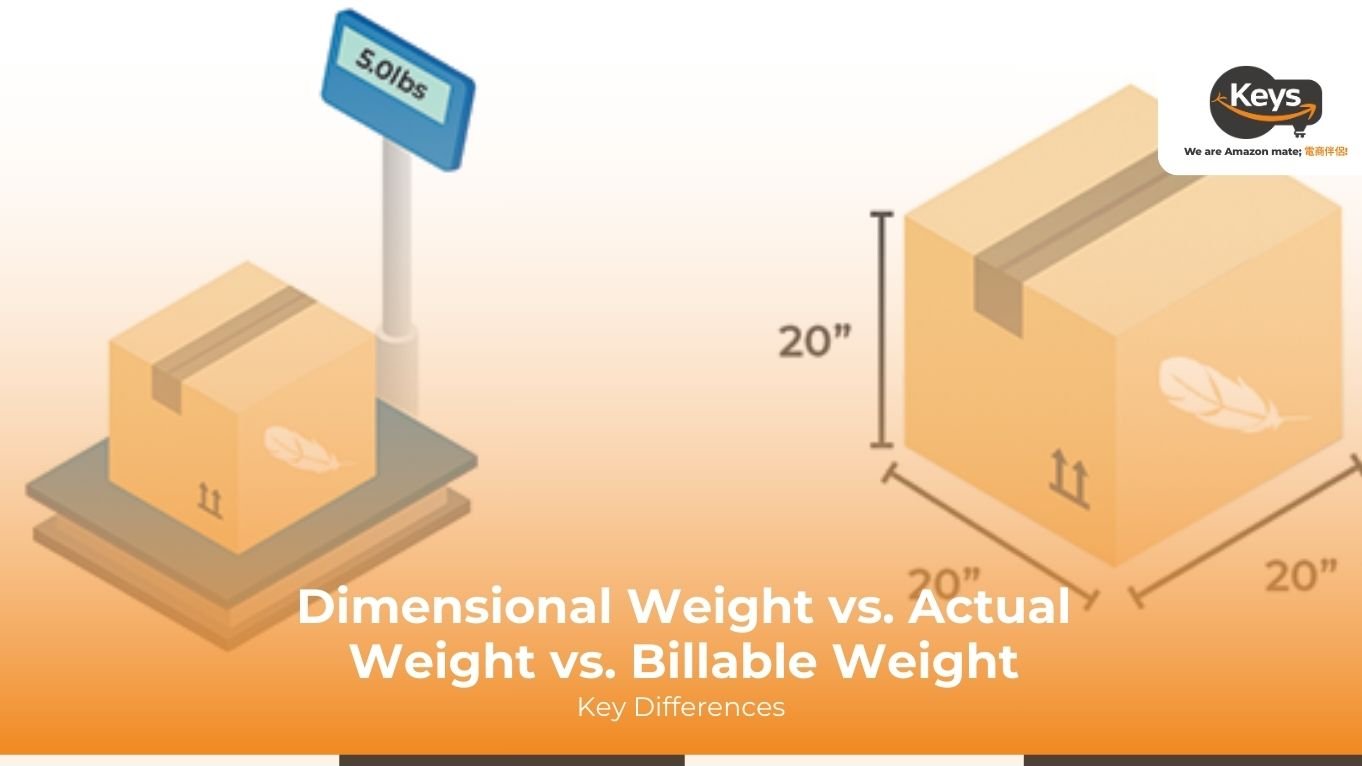

When it comes to shipping costs, understanding the difference between dimensional weight, actual weight, and billable weight is crucial for businesses seeking to optimize their logistics and minimize expenses. This article examines the key differences between these weights and their impact on shipping decisions.

What is Actual Weight?

In logistics, actual weight refers to the physical weight of an item, measured in kilograms or pounds. This is the total weight of the product, including its packaging and any additional components. Actual weight is critical in determining shipping costs, as it directly impacts the overall weight of the shipment.

What is Dimensional Weight?

Dimensional weight, also known as volumetric weight, is a calculation used by shipping companies to account for the space a package occupies with its actual weight. Instead of solely charging based on weight, carriers often use dimensional weight to ensure that lightweight but bulky items are priced reasonably. This is particularly important for air freight and other forms of transportation where space is limited. The formula for dimensional weight involves multiplying the package’s length, width, and height and then dividing by a divisor specified by the carrier (usually 166 or 139, depending on the shipping method).

How Dimensional Weight Is Calculated?

Dimensional weight is a key concept in the logistics industry, particularly for carriers like UPS and FedEx, to help determine shipping costs based on the space a package occupies, rather than just its actual weight. Calculating dimensional weight involves several steps:

- Step 1: Measure the length, width, and height of your package at its longest point, including any bulges or irregularities.

- Step 2: Round up measurements to the nearest whole number to ensure that even small increases in size are accounted for, which may affect the final shipping cost.

- Step 3: Multiply the length, width, and height to determine the cubic size of the package. For example, a package that measures 30 inches in length, 12 inches in width, and 12 inches in height would have a cubic size of 4,320 cubic inches (30 x 12 x 12).

- Step 4: Divide the cubic size by the DIM divisor. The DIM divisor is a factor set by the carrier, such as UPS or FedEx, and it represents the number of cubic inches per pound. Common DIM divisors used by carriers are 166 or 139, but these may vary depending on the carrier and shipping service.

What is Billable Weight?

Billable weight is determined by either the actual weight or the dimensional weight of a shipment, whichever is greater. For example, a large but lightweight package (like an oversized box filled with feathers) will be charged based on its dimensional weight, as it occupies more space in a carrier’s vehicle or aircraft than a smaller, heavier box. Billable weight ensures that carriers are compensated fairly for both the physical weight and the space a package takes up during transit.

Dimensional Weight vs. Actual Weight: Key Difference

Actual weight refers to the physical weight of the package, which is simply measured by scales at the warehouse or during transit. On the other hand, dimensional weight is calculated based on the package’s volume. This is especially important for large, lightweight items, where the size of the parcel may require more space in the shipping vehicle than its weight would suggest.

| Factor | Dimensional Weight | Actual Weight |

| Definition | Weight based on volume (L x W x H) | Actual physical weight of the item |

| Calculation | Volume-based formula (L x W x H / Dimensional Factor) | Measured directly using scales |

| When it’s used | For large, lightweight packages | For packages with significant weight |

| Impact on Costs | Can significantly increase shipping costs for bulky but light items | Directly determines the shipping cost |

How to optimize your shipping costs?

Optimize packaging to lower expenses

By selecting the right size and materials for packaging, you can avoid excess dimensional weight charges, which can significantly increase shipping costs. Using lightweight yet durable packaging materials, such as corrugated cardboard or biodegradable foam, helps minimize the overall weight without compromising the safety of the goods during transit. Additionally, adopting standard box sizes that fit your product range and aligning packaging to the carrier’s dimension rules will ensure that you are not overpaying for shipping.

Re-kit your products

Re-kitting involves adjusting the way products are grouped or bundled for shipment. This can include consolidating smaller items into a single package or modifying the way products are prepped for transit to fit better into standard shipping boxes. By re-kitting products, businesses can take advantage of lower rates for consolidated shipments.

For example, sending multiple small packages together as a single larger shipment reduces the shipping cost per unit. Not only does this method save on carrier charges, but it can also minimize the chances of damage during transit, improving product integrity and customer satisfaction.

Collaborate with a shipping specialist or 3PL provider

One of the most effective ways to optimize shipping costs is by partnering with a third-party logistics (3PL) provider or a shipping specialist. These experts can leverage their industry knowledge, network, and technology to help reduce expenses.

A 3PL provider can negotiate bulk shipping rates with carriers, offering better rates than most businesses can secure on their own. They also utilize advanced technology, such as transportation management systems (TMS), which optimize routes, track shipments, and forecast demand.

Moreover, outsourcing fulfillment and shipping to a 3PL allows businesses to focus on their core operations, while the provider ensures that shipments are managed in the most cost-efficient way possible. This collaboration can also offer access to specialized services, such as international shipping, that may be difficult or costly to manage in-house.

Dimensional weight is based on the volume of the package, while actual weight refers to its real weight. Billable weight, which determines the shipping cost, is calculated by comparing both dimensional and actual weights and using the higher of the two. By recognizing these distinctions, businesses can better manage shipping expenses and avoid unexpected costs, ensuring more accurate pricing and efficient logistics strategies.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)