In this article, we explore the concept and importance of Finished Goods Inventory for businesses operating in modern supply chains. Proper management of finished goods ensures operational efficiency, minimizes waste, and maintains product quality. Companies across manufacturing, retail, and e-commerce rely on accurate inventory to meet demand and optimize costs. Understanding the processes, calculation methods, and best practices is essential for effective inventory management.

What is finished goods inventory?

Finished Goods Inventory refers to the stock of products that have completed the production process but have not yet been sold or distributed to customers. This inventory represents a company’s tangible output ready for sale and is a key component of current assets in financial statements. Finished goods are distinct from raw materials and work-in-progress items, as they have passed all stages of manufacturing, including assembly, quality control, and packaging, making them market-ready.

Proper management of finished goods inventory ensures that businesses can meet customer demand promptly without overstocking, which ties up capital unnecessarily. It also provides a clear snapshot of the company’s production efficiency and operational readiness. For manufacturing and distribution companies, monitoring finished goods inventory helps in planning shipping schedules, optimizing warehouse space, and ensuring that supply aligns with sales forecasts.

Goods Inventory is Essential

Maintaining an accurate finished goods inventory is crucial for businesses to ensure operational efficiency, financial accuracy, and customer satisfaction. Below are the key roles and benefits of managing finished goods inventory effectively.

Role in financial planning and budgeting

Finished goods inventory directly impacts a company’s balance sheet and working capital. Accurate tracking allows finance teams to allocate resources efficiently and plan budgets for procurement, production, and distribution. It helps estimate cost of goods sold (COGS) and profit margins accurately, providing managers with reliable data for decision-making. Additionally, knowing inventory levels enables strategic investment in production capacity or marketing campaigns without overextending financial resources.

Tracking current assets

Finished goods inventory represents a significant portion of a company’s current assets. Monitoring these assets ensures that the company maintains liquidity while managing stock levels effectively. Accurate tracking helps prevent overstocking or understocking, which can lead to excessive holding costs or lost sales opportunities. Advanced inventory systems can integrate with ERP solutions to provide real-time insights, offering a clear view of asset allocation and inventory turnover.

Waste reduction and process optimization

Effective finished goods inventory management reduces spoilage, obsolescence, and overproduction. By tracking products through every stage of the supply chain, companies can identify inefficiencies in production, packaging, or storage. Optimizing inventory processes minimizes waste, improves throughput, and ensures that resources are utilized efficiently. This also contributes to sustainability goals by reducing unnecessary disposal of unsold products.

Preventing stockouts

Maintaining sufficient finished goods inventory is essential to meet customer demand without interruption. Stockouts can lead to lost revenue, decreased customer satisfaction, and potential damage to brand reputation. By analyzing historical sales data and integrating demand forecasting, businesses can ensure inventory levels are sufficient to fulfill orders. Timely replenishment and strategic buffer stock help maintain continuous supply while avoiding excess inventory costs.

How to Calculate Finished Goods Inventory

Calculating Finished Goods Inventory accurately is critical for financial reporting, production planning, and operational efficiency. Businesses need to follow structured steps to ensure inventory values are correct, which also influences cost of goods sold (COGS), balance sheet accuracy, and resource allocation. Below are the key steps and examples to guide this process.

Step 1: Determine the reporting period

The first step in calculating finished goods inventory is to define the reporting period. This could be monthly, quarterly, or annually depending on your accounting or operational requirements. Establishing a consistent reporting period ensures that inventory assessments are comparable over time, allowing managers to track trends and make informed decisions. It is important to align the reporting period with production cycles and sales patterns to capture an accurate snapshot of inventory levels. Proper timing helps identify seasonal variations and plan for future demand efficiently.

Step 2: Collect required financial and production data

Next, gather all necessary data from production and financial records. This includes raw material costs, labor, overheads, work-in-progress details, and finished product quantities. Accurate and comprehensive data ensures that calculations reflect true production costs. Integration with ERP or inventory management systems can streamline data collection, reduce manual errors, and provide real-time visibility into inventory movements. Cross-checking data against purchase orders, production logs, and quality control records is also essential to maintain reliability.

Step 3: Calculate COGM and COGS

Once data is collected, calculate the Cost of Goods Manufactured (COGM) and Cost of Goods Sold (COGS). COGM represents the total production cost of finished goods during the reporting period, including materials, labor, and overhead. COGS accounts for the cost of inventory sold to customers during the same period. These calculations are fundamental in determining the value of remaining finished goods inventory. Accurate computation of COGM and COGS allows companies to assess profitability, adjust pricing strategies, and make informed operational decisions.

Step 4: Apply the formula for finished goods inventory

After determining COGM and COGS, the standard formula is applied:

Finished Goods Inventory = Beginning Inventory + COGM – COGS

This formula calculates the ending inventory at the close of the reporting period. Beginning inventory is the value carried over from the previous period, COGM is the production cost of completed goods, and COGS is the cost of goods sold. Applying this formula accurately ensures financial statements reflect true asset value and provides a reliable basis for management decisions.

Worked calculation examples of calculating finished goods

Consider a company that starts the month with $50,000 in finished goods inventory. During the month, the COGM is $120,000, and COGS is $100,000. Using the formula:

Finished Goods Inventory = $50,000 + $120,000 – $100,000 = $70,000

This example demonstrates how production and sales data are integrated to calculate accurate inventory values. Companies can perform similar calculations for multiple products, adjusting for units produced, unit costs, and applicable overheads. Regularly applying such calculations helps monitor inventory trends, identify inefficiencies, and support budgeting, financial planning, and operational strategy.

Valuation & Accounting Considerations of Finished Goods Inventory

Proper valuation of Finished Goods Inventory is essential for accurate financial reporting, compliance, and business decision-making. Inventory valuation directly affects the balance sheet, cost of goods sold (COGS), and profitability calculations. Companies must adopt consistent accounting methods to ensure transparency and comparability across reporting periods.

Common valuation methods include:

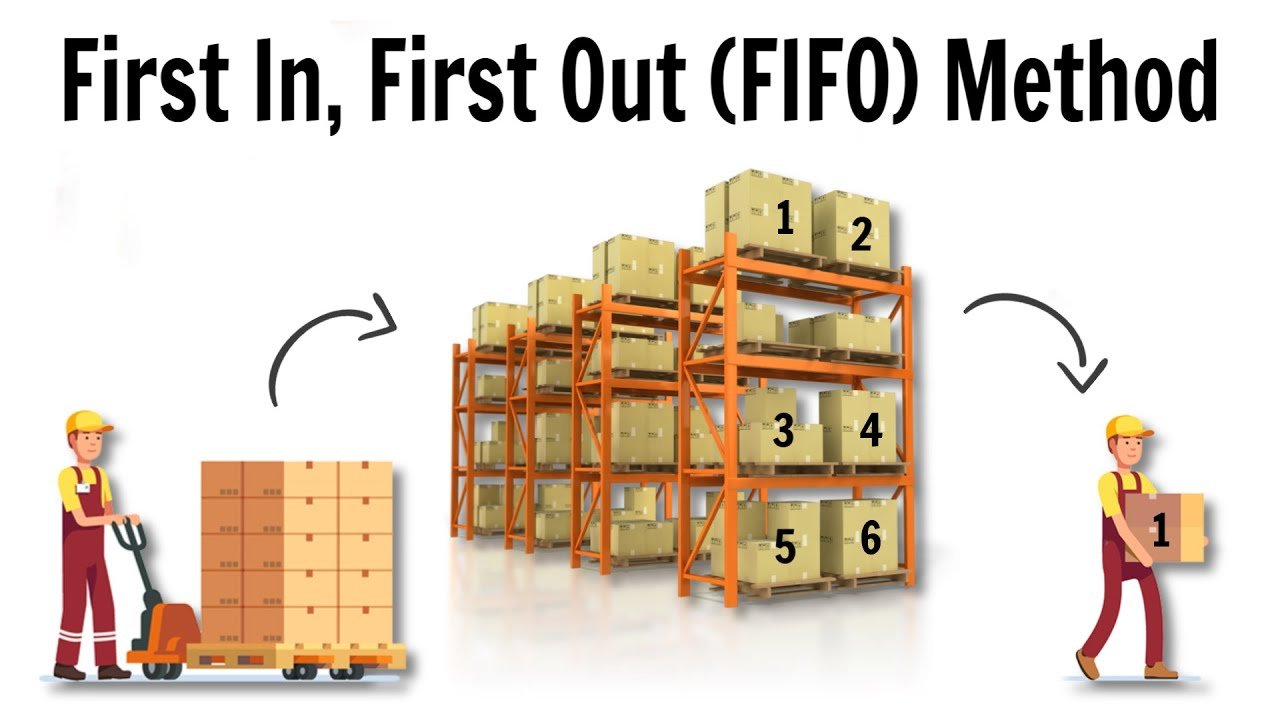

- First-In, First-Out (FIFO): Assumes the oldest inventory is sold first. It is widely used in industries with perishable goods to minimize spoilage and reflect current market costs.

- Last-In, First-Out (LIFO): Assumes the most recently produced goods are sold first. While less common in perishable goods, it may be used for products where prices fluctuate significantly.

- Weighted Average Cost: Calculates the average cost of all units in inventory, smoothing out price variations over time. This method is useful for businesses producing large volumes of similar goods.

- Standard Costing: Uses predetermined costs for materials, labor, and overhead to value finished goods. Variances are tracked and adjusted in accounting records to reflect actual costs.

In addition to selecting the valuation method, companies must ensure compliance with GAAP (Generally Accepted Accounting Principles) or IFRS (International Financial Reporting Standards), depending on jurisdiction. Proper documentation of inventory, regular physical counts, and reconciliation with accounting records are critical. Effective valuation practices not only support accurate reporting but also inform pricing strategies, budgeting, and financial planning.

Performance Benchmarks & KPIs

Monitoring Finished Goods Inventory through performance benchmarks and key performance indicators (KPIs) is crucial for operational efficiency. KPIs help companies track inventory turnover, stock accuracy, and fulfillment efficiency, providing actionable insights into warehouse performance and supply chain health.

Common KPIs include:

- Inventory Turnover Ratio: Measures how many times inventory is sold and replaced over a period, helping evaluate storage efficiency and sales alignment.

- Days of Inventory on Hand (DOH): Indicates how long inventory stays in the warehouse before sale, highlighting potential overstocking or understocking issues.

- Stock Accuracy: Tracks the discrepancy between recorded inventory and actual stock, which is vital for preventing shortages or excess.

- Order Fulfillment Rate: Evaluates the percentage of orders fulfilled on time and in full, reflecting warehouse efficiency and customer satisfaction.

- Carrying Cost of Inventory: Assesses financial impact, including storage, depreciation, and opportunity costs, guiding budget allocation and operational optimization.

Tracking these KPIs enables businesses to make informed decisions, optimize inventory management, and align production with market demand effectively.

Best Practices for Managing Finished Goods Inventory

Efficient management of Finished Goods Inventory requires implementing strategic processes, adopting technology, and aligning inventory with demand forecasts. These practices help reduce waste, improve turnover, and support business growth.

Efficient inventory management processes

Structured processes like FIFO ensure older stock is sold first, reducing waste and spoilage. Regular cycle counts and physical audits help detect discrepancies between recorded and actual inventory. Standardized handling, labeling, and storage locations streamline warehouse operations. Proper documentation of receipts, transfers, and shipments ensures traceability. These practices maintain accuracy, optimize space, and improve overall fulfillment efficiency.

Technology and automation adoption

Using WMS and ERP integration provides real-time visibility of finished goods inventory, locations, and expiration dates. Automated picking, packing, and barcode scanning reduce errors and increase speed. IoT sensors monitor storage conditions continuously. Integration with e-commerce and shipping platforms streamlines order processing. Technology adoption enhances efficiency, minimizes labor costs, and supports scalable inventory management.

Aligning inventory with demand forecasting

Aligning inventory with demand forecasts prevents overstocking and stockouts. Historical sales, seasonal trends, and market analysis guide production and stocking levels. Predictive analytics improve accuracy for replenishment and resource planning. Coordination between procurement, production, and logistics ensures inventory matches customer demand. This alignment reduces holding costs, prevents waste, and ensures timely order fulfillment.

Maintaining an accurate Finished Goods Inventory is crucial for operational success, financial transparency, and customer satisfaction. By implementing best practices, leveraging technology, and aligning inventory with demand, businesses can optimize production and reduce losses. Effective inventory management supports strategic decision-making and enhances supply chain resilience. Overall, finished goods inventory plays a central role in maximizing efficiency and profitability across all sectors.

Looking to optimize your finished goods inventory and streamline logistics? Keys Logistics offers end-to-end solutions for storage, fulfillment, and distribution. Our advanced WMS and TMS integrate with Shopify, Amazon, TikTok Shop, and more for seamless operations. With a global network of 500+ trusted carriers, we ensure reliable, fast, and compliant delivery. Contact us today to scale your supply chain, reduce costs, and maintain product quality at every step.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)