In supply chain and inventory management, mastering the Inventory Turnover Ratio is essential for maintaining operational efficiency and financial health. This metric reveals how effectively a company sells and replaces its inventory over time. A strong turnover rate indicates healthy demand and optimal stock levels, while a poor ratio may signal overstocking or slow-moving goods. In this guide, we’ll explore how to calculate, interpret, and improve your Inventory Turnover Ratio to enhance profitability and performance.

What Is Inventory Turnover?

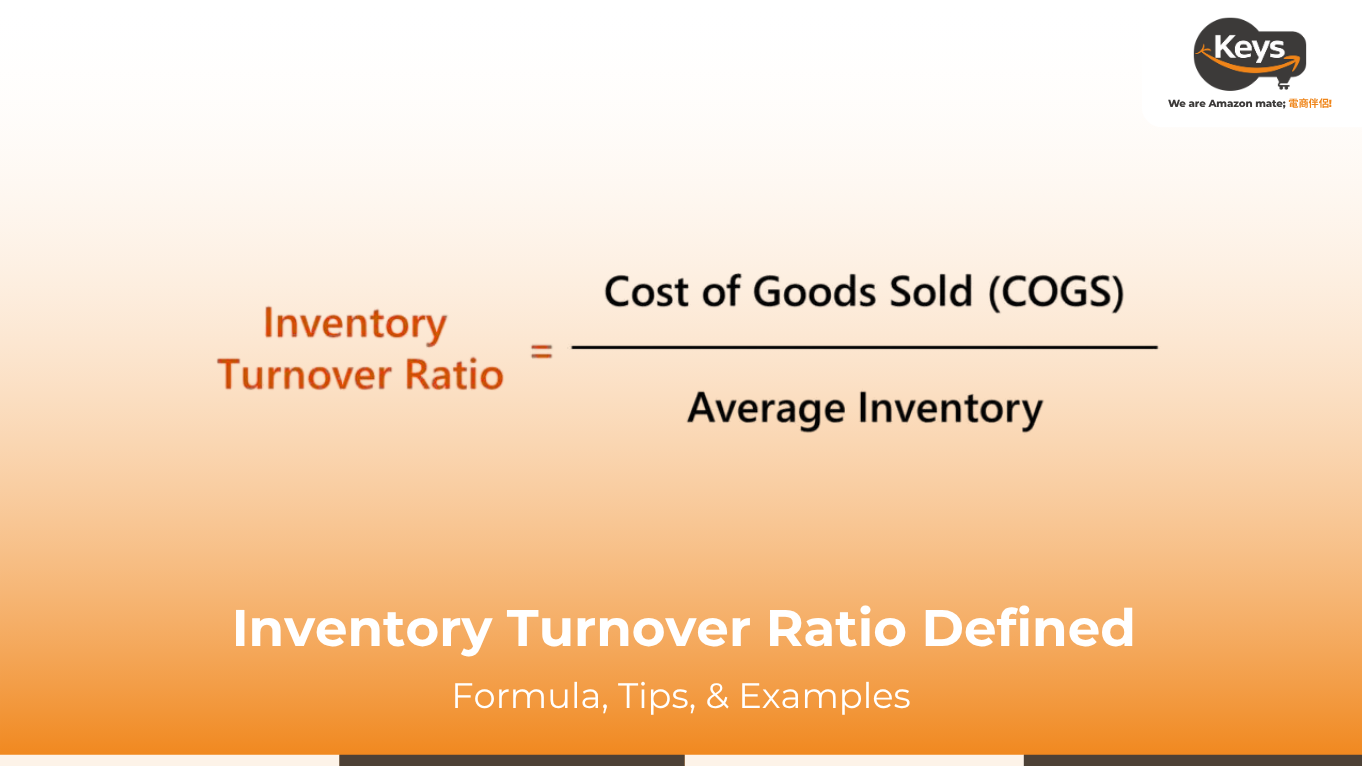

Inventory turnover is a key performance indicator used in logistics and supply chain management to assess how efficiently a company sells and replaces its inventory over a specific time period. It is typically expressed as the Inventory Turnover Ratio, calculated by dividing the cost of goods sold (COGS) by the average inventory during that period. This ratio reveals how often stock is cycled through – helping businesses evaluate product demand, inventory purchasing practices, and warehousing efficiency.

Understanding the Inventory Turnover Ratio

The Inventory Turnover Ratio is a critical metric in logistics and supply chain management that measures how frequently a company sells and replenishes its inventory over a defined period. By comparing the cost of goods sold (COGS) to the average inventory, this ratio provides insights into the efficiency of inventory utilization and sales performance. A high inventory turnover ratio typically reflects strong demand, streamlined operations, and minimal excess stock. Conversely, a low ratio may indicate overstocking, poor sales, or inefficient inventory management.

Detailed Explanation of Inventory Turnover Ratio

The Inventory Turnover Ratio provides a comprehensive view of how efficiently a company converts its inventory into sales within a specific timeframe. It is calculated by dividing the cost of goods sold (COGS) by the average inventory held during the same period. This ratio reflects the number of times inventory is sold and replaced, offering valuable insight into demand forecasting, purchasing strategy, and supply chain performance.

A higher Inventory Turnover Ratio typically suggests that a business is selling products quickly and maintaining lean inventory levels, which minimizes holding costs and reduces the risk of obsolescence. On the other hand, a lower ratio may point to overstocking, slow-moving items, or misaligned supply-demand dynamics. In logistics and operations, this metric is essential for evaluating warehousing efficiency, improving cash flow, and aligning procurement practices with actual sales trends.

How the Inventory Turnover Ratio Works

Think of the Inventory Turnover ratio as a speedometer for your stock, showing how quickly you sell and replace inventory over a period. It’s calculated simply by dividing your Cost of Goods Sold (COGS) by your average inventory value for that time.Using average inventory provides a more stable picture than just end-of-period stock, smoothing out seasonal changes.

A higher ratio generally points to efficient sales and lean operations, while a lower one might signal slower movement or potential overstocking. Tracking this key metric helps logistics teams make smarter decisions about purchasing and warehousing strategies.

How to Calculate Inventory Turnover Ratio (ITR)

Here’s a breakdown of the components and the calculation process:

Cost of Goods Sold (COGS)

Cost of Goods Sold (COGS) represents the total cost incurred by a company to produce the goods that were sold during a specific period. This figure includes direct costs such as materials and labor associated with the production of goods. Accurately determining COGS is crucial, as it directly impacts the Inventory Turnover Ratio calculation.

Average Inventory (AI)

Average Inventory is calculated to provide a more stable measure of inventory levels over time. It is determined by adding the beginning inventory and the ending inventory for the period and then dividing by two. This calculation helps smooth out seasonal fluctuations and provides a clearer picture of inventory management.

Calculating the Inventory Turnover Ratio

The Inventory Turnover Ratio is calculated using the following formula:

- Inventory Turnover Ratio= Cost of Goods Sold (COGS)/Average Inventory

By applying this formula, businesses can determine how many times their inventory is sold and replaced within the specified period. A higher ratio typically indicates efficient inventory management and strong sales performance, while a lower ratio may suggest overstocking or weak sales.

Examples of Inventory Turnover Ratio

To illustrate the calculation, consider a company with a COGS of $500,000 and an average inventory of $100,000. The Inventory Turnover Ratio would be calculated as follows:

- Inventory Turnover Ratio = 500.000/100.000 = 5.

This result indicates that the company sold and replaced its inventory five times during the year. Regularly monitoring this ratio can help businesses make informed decisions regarding inventory management and operational efficiency.

Why Inventory Turnover Ratio Matters

The Inventory Turnover Ratio is a vital metric for businesses as it reflects how efficiently inventory is managed and how effectively sales are generated. A high turnover ratio indicates that a company is selling its products quickly, which can lead to improved cash flow and reduced holding costs.

Conversely, a low ratio may suggest overstocking or weak demand, prompting businesses to reassess their inventory management strategies. Understanding this ratio helps companies optimize their stock levels, align inventory with market demand, and enhance overall operational efficiency.

What Is the Ideal Inventory Turnover Ratio?

The ideal Inventory Turnover Ratio varies by industry and product type. Generally, a higher ratio is preferred, as it suggests that a company is effectively selling its inventory. For most retail businesses, an ideal turnover ratio typically falls between 5 and 10, indicating that inventory is sold and replenished every one to two months.

However, industries dealing with high-value items, such as luxury goods, may naturally have lower turnover ratios. It’s essential for businesses to benchmark their ratios against industry standards to determine what is considered optimal for their specific market.

How to Address a Low Inventory Turnover Ratio

Addressing a low Inventory Turnover Ratio requires a strategic approach. Here are several effective strategies:

- Reevaluate pricing strategies: Consider adjusting prices to stimulate demand for slow-moving items.

- Enhance marketing efforts: Implement targeted marketing campaigns to raise awareness and drive sales of underperforming products.

- Optimize inventory levels: Reduce excess stock by analyzing sales data and aligning inventory with current market demand.

- Diversify product offerings: Introduce new products that may attract customers and increase overall sales volume.

By taking these steps, businesses can improve their turnover ratios and ensure that their inventory aligns more closely with customer demand.

Why a Higher Inventory Turnover Ratio Is Better

A higher Inventory Turnover Ratio is generally seen as beneficial because it indicates that a company is efficiently selling its products. This efficiency leads to improved cash flow, allowing businesses to reinvest in operations and reduce the costs associated with holding excess inventory. Additionally, a high turnover ratio often reflects strong market demand and effective inventory management practices, which can enhance a company’s competitive position in the market.

Can the Inventory Turnover Ratio Be Too High?

While a high Inventory Turnover Ratio is typically advantageous, it can also pose challenges. If the ratio is excessively high, it may indicate that a company is not maintaining enough inventory to meet customer demand, leading to stockouts and potential lost sales opportunities. Therefore, businesses should aim for a balanced turnover ratio that supports both strong sales and adequate inventory levels to fulfill customer needs without overextending their supply chain.

Defining the Ideal Inventory Turnover Ratio

Defining the ideal Inventory Turnover Ratio involves considering various factors, including industry benchmarks and specific business goals. Companies should analyze their historical turnover ratios and compare them with competitors to identify areas for improvement. Regular monitoring and adjustment of inventory practices can help achieve an optimal turnover ratio that aligns with business objectives and market conditions. This proactive approach ensures that businesses remain agile and responsive to changing consumer demands.

Additional Uses of Inventory Turnover Ratio

The Inventory Turnover Ratio is not only a key performance indicator for assessing sales efficiency but also serves various strategic purposes that can enhance overall business operations. Here are some additional uses of this important metric:

Tracking Turnover Trends

Monitoring the Inventory Turnover Ratio over time allows businesses to identify trends in sales and inventory management. By analyzing these trends, companies can make informed decisions about purchasing, production, and marketing strategies.

For instance, a consistent increase in turnover may indicate growing demand for certain products, prompting businesses to adjust their inventory levels accordingly. Conversely, a declining ratio could signal the need for promotional efforts or a reevaluation of product offerings.

Segmenting Products and SKUs

Segmenting products and SKUs (Stock Keeping Units) based on their Inventory Turnover Ratios enables businesses to gain deeper insights into their inventory performance. By categorizing items according to their sales velocity, seasonal relevance, or profitability, companies can tailor their inventory management strategies to specific segments.

This targeted approach helps optimize stock levels, reduce excess inventory, and enhance overall sales performance. For example, fast-moving items may require more frequent restocking, while slower-moving products might benefit from promotional campaigns to boost sales.

Applying the 80/20 Rule to Inventory Turnover Ratio

The 80/20 Rule, or Pareto Principle, states that approximately 80% of a company’s sales often come from just 20% of its products. By applying this principle to the Inventory Turnover Ratio, businesses can focus their efforts on the key SKUs that drive the majority of their revenue.

Identifying these high-impact items allows companies to prioritize inventory management, marketing, and sales strategies for these products, ensuring they remain well-stocked and visible to customers. This approach not only maximizes sales potential but also minimizes the risk of overstocking less profitable items.

Five Techniques to Optimize Inventory Turnover Ratio

Optimizing your Inventory Turnover Ratio is crucial for enhancing cash flow and improving overall business efficiency. Here are five effective techniques to help you achieve a better turnover ratio:

- Improve demand forecasting: Accurate demand forecasting is essential for maintaining optimal inventory levels. Utilize historical sales data and market trends to predict customer demand more effectively. Implementing inventory management software can help analyze past sales patterns and adjust stock levels accordingly, ensuring you have the right products available when customers need them.

- Enhance marketing strategies: Boosting sales through targeted marketing campaigns can significantly improve your Inventory Turnover Ratio. Create promotions, discounts, or special events that encourage customers to purchase slower-moving items. By increasing demand for these products, you can reduce excess inventory and improve turnover rates.

- Streamline procurement processes: Align your purchasing strategy with actual sales data. Focus on the 20% of products that generate 80% of your sales, as per the Pareto Principle. By prioritizing these high-demand items, you can reduce the risk of overstocking and ensure that your inventory turnover remains healthy.

- Eliminate obsolete stock: Regularly review your inventory to identify and remove obsolete or slow-moving items. Implement markdowns or clearance sales to clear out old stock, freeing up capital and making room for more profitable products. This practice not only improves your turnover ratio but also enhances your overall inventory management.

- Diversify product offerings: Introducing new products or variations can create excitement and urgency among customers, leading to increased sales. By diversifying your product lines, you can attract a broader customer base and improve your Inventory Turnover Ratio. Ensure that new offerings align with market demand to maximize their impact.

Improving Inventory Turnover Ratio with Inventory Management Software

Keys Logistics leverages advanced inventory management software to optimize supply chain efficiency and improve the Inventory Turnover ratio. Using Oracle NetSuite WMS, we streamline warehouse operations, reduce picking errors, and shorten order cycles. Our TMS (Transplace) enhances delivery speed by optimizing routes and lowering shipping costs. ShipHero FMS enables us to process over 2 million orders annually with <1% error rate.

We also integrate with platforms like Shopify and Amazon through ChannelAdvisor to sync inventory in real time. With AfterShip and Power BI, clients gain full visibility and insights to reduce excess stock and boost turnover. These technologies collectively help our clients reduce costs and increase inventory efficiency at scale.

Mastering your Inventory Turnover ratio is essential for improving supply chain efficiency, reducing holding costs, and boosting profitability. Whether you’re addressing low turnover or aiming to optimize stock flow, tracking this metric empowers smarter inventory decisions. By implementing the right tools and strategies, businesses can maintain lean operations while meeting market demand with precision.

Need help accelerating your inventory turnover? Keys Logistics offers cutting-edge warehousing and fulfillment solutions powered by advanced software systems. Contact us today to streamline your inventory and drive measurable results.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)