In e-commerce, accuracy and transparency in shipping are essential. A packing slip is the document that confirms what’s inside a package and supports smooth order fulfillment. This packing slip guide explains what it is, why it matters, and how to use it effectively. From key components to best practices, we’ll cover everything you need to know. With the right approach, packing slips can improve efficiency and customer satisfaction.

What is a Packing Slip?

A packing slip is a document that accompanies a shipment and lists the items included in a package. Unlike invoices or shipping labels, which focus on payment details or delivery addresses, a packing slip serves as a checklist for both the sender and the recipient. It helps verify that the correct products, quantities, and variants are included in the order.

In practice, a packing slip is often printed on plain paper and placed inside the package or attached to the outside in a protective sleeve. It may include information such as the sender’s address, the recipient’s details, order numbers, product descriptions, and notes regarding missing or backordered items.

Think of a packing slip as the communication bridge between warehouse operations and the customer. For businesses, it minimizes errors, ensures transparency, and builds trust. For customers, it provides reassurance that their purchase is correct and complete. That is why every effective packing slip guide highlights its role as an essential document in the shipping process.

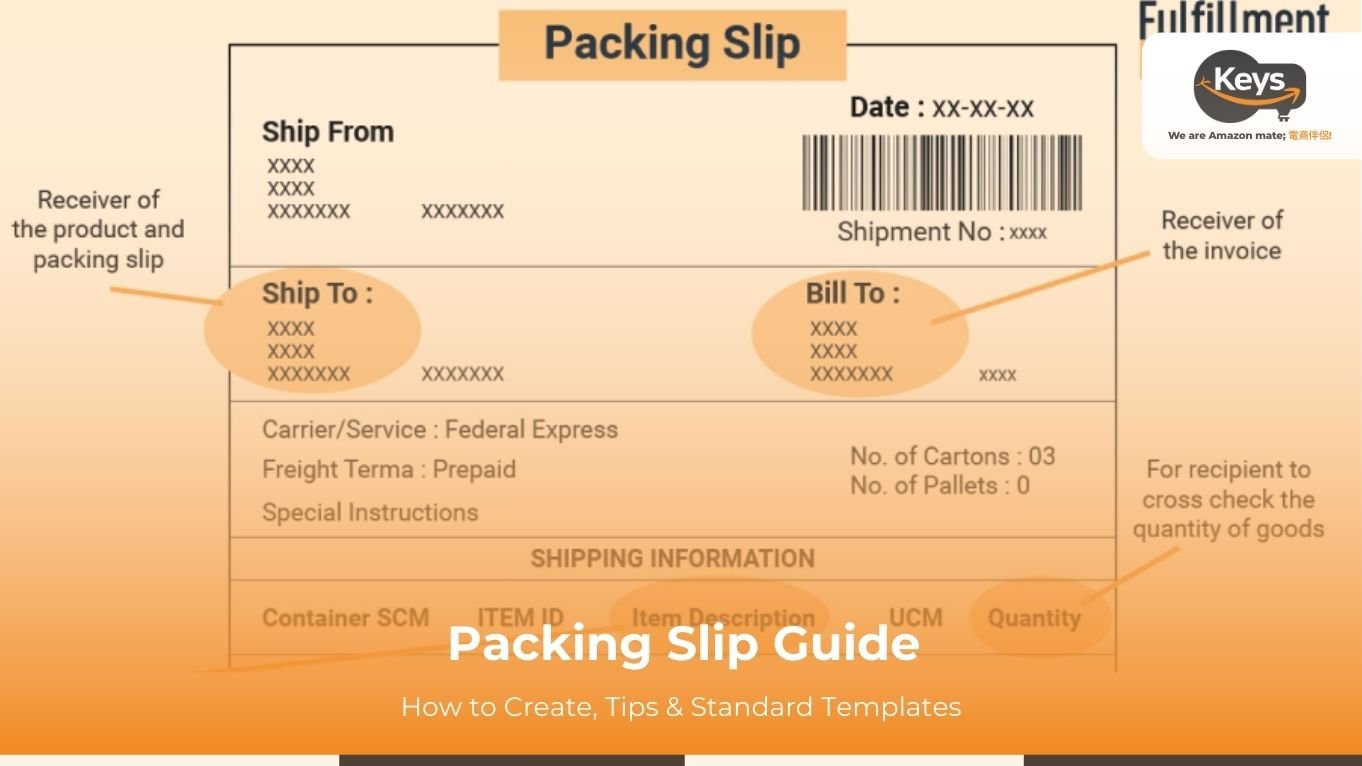

Key Components of a Packing Slip

Any reliable packing slip guide should highlight the importance of including accurate sender, recipient, and order information, along with optional notes that personalize the shipment.

Sender Information

The first detail on any packing slip is the sender’s information. This typically includes the company name, warehouse address, and contact details such as phone number or email. Clear sender information helps customers or carriers trace the package back in case of delivery issues or returns. In professional operations, standardized templates ensure consistency across all orders. Including sender data in your packing slip guide ensures traceability and builds trust with customers.

Recipient information

Equally important is the recipient’s information. The packing slip should clearly show the customer’s full name, shipping address, and contact number. This ensures the order reaches the correct person, even if the external shipping label is damaged. Having this redundancy prevents misdeliveries and gives customers confidence in your process. In every packing slip guide, recipient details are listed as one of the most critical fields.

Order Information

Order information forms the core of a packing slip. It usually includes the order number, date, product names, SKUs (Stock Keeping Units), and quantities. Some businesses also add item descriptions or variant details such as size or color. This information serves as a checklist for warehouse staff during picking and packing, while also helping customers confirm they received exactly what they ordered. Without this field, the packing slip loses much of its value.

Additional notes and salutation

While optional, additional notes and salutations can greatly enhance customer experience. For instance, notes may indicate items that are on backorder, replacements for defective goods, or return instructions. Adding a friendly thank-you message or brand slogan can also leave a positive impression. Including this element in a packing slip guide reminds businesses that packing slips are not just functional—they can also reinforce customer relationships.

Why are Packing Slips Important?

Packing slips may look simple, but they serve multiple roles in ensuring smooth order fulfillment. Beyond listing items, they act as proof of shipment, a communication tool between businesses and customers, and a safeguard against errors. A good packing slip guide always emphasizes these practical benefits that keep operations efficient and customers satisfied.

Verifying all shipment contents

One of the main reasons for using a packing slip is to verify what’s inside a package. Warehouse teams use it as a checklist during the packing process, ensuring that every item matches the customer’s order. On the receiving end, customers can also cross-check the slip with the contents of their box. This double verification minimizes mistakes, reduces disputes, and builds credibility for the seller.

Enhancing customer experience

Packing slips do more than confirm items—they also enhance the unboxing experience. Customers feel reassured when they see a clear record of their purchase inside the package. Businesses often use the slip to include personalized messages, branding elements, or customer support information. This small addition demonstrates professionalism and helps strengthen long-term customer loyalty. A packing slip guide that highlights this aspect shows how functionality and customer care go hand in hand.

Splitting orders

When a single order is shipped in multiple boxes, packing slips become especially important. Each slip lists the items included in that box, making it easier for customers to understand partial shipments. Without this, buyers may think products are missing or lost in transit. Including clear references to backordered or separately shipped items avoids confusion and keeps expectations realistic.

Detecting defective products

Packing slips can also play a role in quality control. By documenting what was shipped, businesses can track defective or returned items more easily. If a customer reports a problem, the slip serves as a reference to confirm whether the item was part of the original shipment. This transparency helps resolve issues quickly and reduces disputes. For operations teams, it’s a practical way to tie together order data and product performance.

Estimating value for buyers

While not a replacement for invoices, packing slips give customers an approximate sense of order value. By listing items and quantities, they provide transparency into the scope of the shipment. Some businesses also include SKU codes that help buyers identify specific product lines. This information can be especially helpful for corporate clients or bulk buyers who need to reconcile received goods with purchase records. A packing slip guide that mentions this feature highlights its usefulness beyond simple packing.

How to Create Packing Slips: A Complete Step-by-Step Guide

Creating an effective packing slip doesn’t have to be complicated. With the right process, you can design slips that are accurate, professional, and easy for both staff and customers to understand. A packing slip guide usually breaks this process down into three simple steps: gathering the right data, filling it into a clear template, and saving or printing the slip for use.

Gather all the data

The first step in creating a packing slip is to gather all necessary information. This includes customer details, product descriptions, SKUs, order numbers, and any special notes such as backorders or replacements. Collecting accurate data at this stage prevents errors later in fulfillment. Many businesses integrate their e-commerce platforms directly with order management systems, ensuring the data flows automatically. A reliable packing slip guide always stresses the importance of accurate data collection.

Fill data in the templates

Once you have the data, the next step is to place it into a standardized template. Templates ensure that slips are consistent across all shipments, making them easier for staff and customers to read. Most businesses use digital tools like Microsoft Word, Excel, or specialized software to generate slips quickly. Adding your company’s branding, such as a logo or slogan, can also make the slip more professional. In any packing slip guide, this step is where clarity and presentation matter most.

Save or print slips

The final step is to save a digital version and print a physical copy. Digital versions provide an archive for internal reference and make it easier to resend slips if customers request them. Printed slips should be included inside the package or attached securely in a protective sleeve. Some businesses use eco-friendly practices by offering digital packing slips accessible via QR codes. Whether printed or digital, this stage ensures that the packing slip fulfills its role in the order fulfillment process.

Packing Slips vs Invoices vs Shipping Labels: Key Differences

In a complete order fulfillment workflow, multiple documents work together to ensure accuracy, compliance, and smooth delivery. The packing slip, invoice, and shipping label may appear similar at first glance, but they complement each other by serving unique functions. A professional packing slip guide doesn’t just define these documents individually – it shows how they interact to create a seamless customer experience. The comparison table below outlines their distinct roles.

|

Document Type |

Purpose | Key Contents |

Placement |

| Packing Slip |

Confirms shipment contents |

Order number, item list, SKUs, quantities, notes |

Inside the package or attached in sleeve |

| Invoice |

Requests payment |

Product prices, taxes, discounts, total amount due |

Sent digitally or included with shipment |

| Shipping Label |

Ensures delivery |

Recipient’s address, barcode, tracking information |

Outside the package, visible to carriers |

Best Practices for Using Packing Slips in Business

A well-prepared packing slip guide should not only describe what goes into the slip but also how to manage it effectively. By following best practices, businesses can turn a routine document into a tool that supports efficiency and customer satisfaction.

Provide all key information

A packing slip is only effective when it includes every critical detail. Missing order numbers, incomplete product descriptions, or absent recipient data can create unnecessary confusion. By ensuring all required fields are present, businesses provide clarity for both staff and customers. Any packing slip guide should emphasize the value of thoroughness – because a single missing item can undermine the purpose of the document.

Ensure the slip aligns with the order

One of the best practices is to make sure the packing slip always reflects the actual order. If substitutions, backorders, or partial shipments occur, these changes should be clearly indicated. This prevents misunderstandings and builds transparency with customers. Aligning the slip with the order data also helps internal teams maintain accurate records. A professional packing slip guide always stresses this alignment step.

Mark items that are missing or on backorder

Sometimes not all items are available at the time of shipping, especially in large or split orders. Clearly marking items as “backordered” or “shipped separately” sets realistic expectations for customers. Without this, buyers may assume products are missing or lost. Documenting missing items on the packing slip also helps customer service teams respond quickly to inquiries. Including this practice in a packing slip guide helps businesses reduce disputes.

Maintain a standardized layout

Consistency in layout makes packing slips easy to read and use. A standardized format ensures that staff can process orders quickly and customers can recognize your brand’s professionalism. This includes keeping sender and recipient information at the top, followed by order details in a clear table. Adding branding elements like logos can also reinforce identity. A structured layout is a detail no serious packing slip guide overlooks.

Store a digital version

While the physical copy travels with the package, businesses should also store digital versions of all packing slips. Digital records help track order history, manage returns, and provide quick reference in case of disputes. Storing slips electronically also supports sustainability efforts by reducing paper waste. A strong packing slip guide always recommends combining digital storage with printed versions for maximum efficiency.

Position the packing slip correctly

Placement of the packing slip might seem trivial, but it impacts customer experience. If placed carelessly, it may be lost or damaged. The best practice is to either place it inside the package in a visible spot or attach it securely on the outside in a protective sleeve. Clear positioning ensures customers see it immediately upon receiving the package. Such practical details often define the difference between a good and great packing slip guide.

Educate and guide your staff

Even the most well-designed packing slip is useless if staff don’t know how to use it. Training warehouse and fulfillment teams on how to read, verify, and update packing slips ensures consistency. Regular refreshers also help employees adapt to changes in templates or software. Educated staff minimize errors and improve workflow efficiency. A complete packing slip guide always includes training as a cornerstone of best practices.

Standard Packing Slip Templates

Not every business has time to design packing slips from scratch, which is why standard templates are so useful. They provide a ready-made structure that covers all essential details, from sender and recipient information to product lists and order numbers. Using a consistent template also ensures professionalism and reduces the chance of missing key information. A practical packing slip guide usually recommends customizing templates with your brand identity while keeping the layout simple and functional.

Example of a Standard Packing Slip Template:

- Header Section: Company logo, sender address, contact information.

- Recipient Section: Customer’s name, delivery address, phone number.

Order Details: Order number, order date, customer reference code. - Product Table: Item description, SKU, quantity ordered, quantity shipped, notes for backorder or missing items.

- Footer Section: Additional notes, thank-you message, return instructions, customer support contact.

By adopting a standardized template, businesses can save time, improve accuracy, and offer customers a smoother unboxing experience. Whether you use pre-built software templates or create your own, keeping the format consistent ensures every shipment meets professional standards.

Packing slips are more than just shipping paperwork—they are the bridge that connects warehouse operations to customer satisfaction. A well-structured slip reduces errors, improves communication, and sets a professional standard for every order shipped. As this packing slip guide shows, mastering packing slips means mastering part of the fulfillment process itself. With the right templates, best practices, and staff training, businesses can turn a simple document into a tool that builds trust and loyalty. In today’s fast-moving e-commerce world, even the smallest detail like a packing slip makes a big difference.

Let Keys Logistics help you simplify your global order fulfillment process. From overseas warehousing to last-mile delivery, we handle every step with speed and accuracy. Our end-to-end services include packing slip management, return handling, and seamless e-commerce integration. With strategically located warehouses in the US, UK, and Asia, your products reach customers faster. Contact us today and transform your supply chain into a competitive advantage!

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)