Cost per unit is a foundational business and financial analysis metric, offering insights into production efficiency and overall cost structure. Companies can make informed decisions about pricing, scaling, and process improvements by calculating this figure. This article of Key Logistics below breaks down the cost per unit formula, demonstrates how to calculate it accurately, and shares practical methods for reducing unit costs to boost profitability.

What is cost per unit? How to calculator it?

Cost per unit is a key financial metric used to determine how much a business costs to produce or distribute one unit of a product or service. In logistics and supply chain management, this figure helps assess operational efficiency, identify cost-saving opportunities, and ensure pricing strategies remain profitable. It is calculated by dividing the total of fixed and variable costs by the number of units produced or handled.

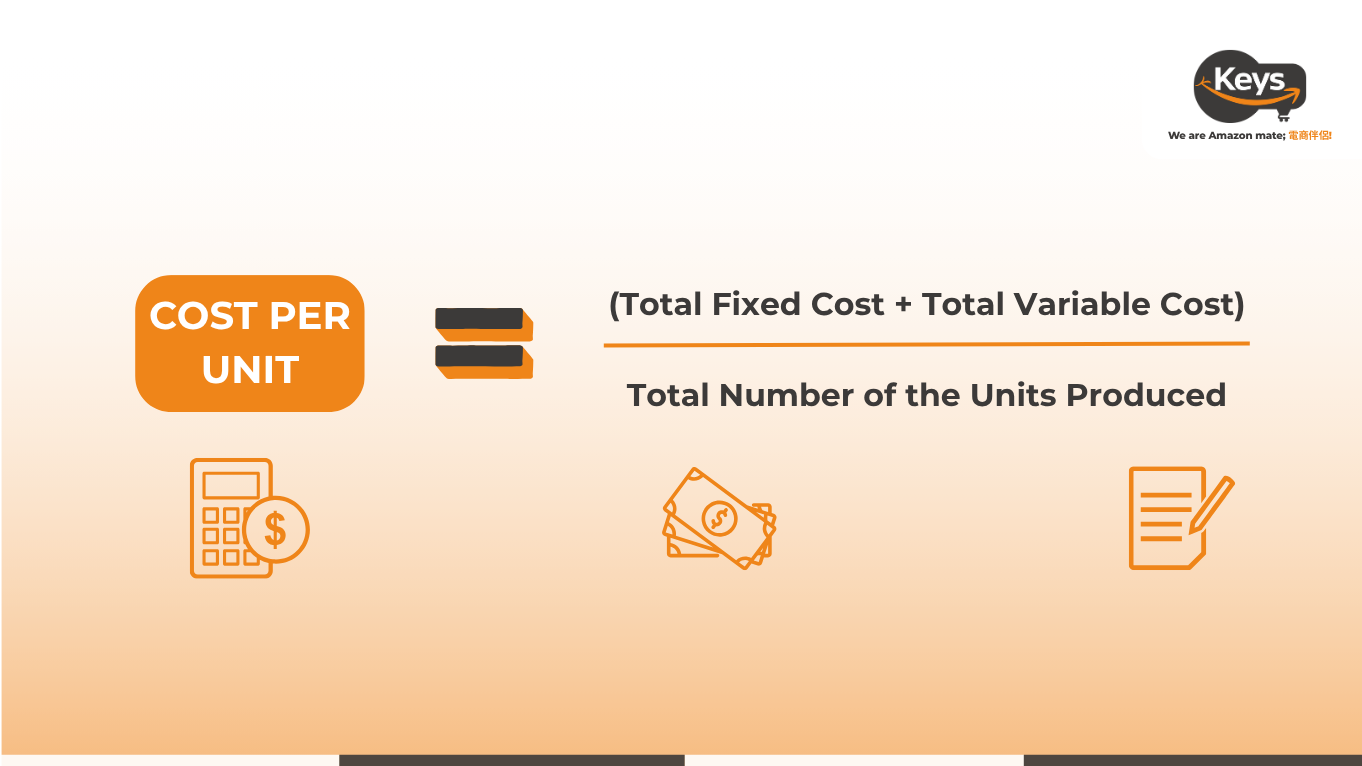

The formula is straightforward:

Cost Per Unit = (Total Fixed Costs + Total Variable Costs) / Total Units Produced

To accurately determine the cost per unit, it’s essential to distinguish between fixed and variable costs. Here’s a brief explanation:

Fixed Costs (Total Fixed Costs)

Fixed costs are overhead expenses that remain unchanged regardless of how many units are produced. In a logistics setting, these typically include:

- Lease payments for warehouses or office facilities.

- Annual salaries of administrative staff or salaried supervisors.

- Equipment leases (e.g., conveyors, forklifts, IT systems).

- Business insurance and property taxes.

While these costs are generally stable, they can rise when expanding capacity. For instance, opening a second warehouse to meet higher demand would raise your overall fixed cost baseline.

Variable Costs (Total Variable Costs)

Variable costs shift in proportion to production volume. These expenses grow or shrink depending on how much is being manufactured, packed, or shipped. In logistics, variable costs often include:

- Hourly wages for warehouse operators or fulfillment workers.

- Packaging supplies, labels, and shipping cartons.

- Fuel costs, utility bills, or software subscriptions based on usage.

- Freight charges or outsourced delivery fees.

- Advertising or marketing tied to per-unit campaigns.

Reducing variable costs can involve negotiating with suppliers, improving warehouse workflows, or adopting automation to enhance throughput without raising expenses.

Units Produced (Total Units Produced)

This figure represents the total number of items created or handled within a specific period—such as monthly production volume or a single fulfillment cycle. To ensure accuracy, the timeframe used for counting units must match the period for calculating fixed and variable costs.

Example of cost per unit calculation

Let’s take BrightPack Solutions as an example. This packaging supply company produces 2,000 corrugated shipping boxes per month for e-commerce clients. Its operations include custom printing, cutting, and assembly in a regional warehouse.

Fixed Costs:

- Warehouse lease: $2,000/month

- Business insurance: $300/month

- Equipment rental (die-cutting machines): $700/month

- Total Fixed Costs = $3,000

Variable Costs:

-

- Cardboard sheets and ink: $2,400

- Hourly wages for production workers: $2,800

- Shipping labels and adhesives: $600

- Total Variable Costs = $5,800

Now applying the cost per unit formula:

Cost Per Unit = ($3,000 + $5,800) / 2,000 = $8,800 / 2,000 = $4.40

This means each box costs $4.40 to produce and prepare for delivery. BrightPack would need to set the selling price above this break-even figure to remain competitive and profitable.

The critical role of cost per unit in business success

In the logistics industry, cost per unit is critical in driving profitability, pricing strategies, and operational decisions. Understanding this metric allows businesses to control expenses and optimize their supply chains in a competitive, cost-sensitive market. With rising freight rates, fuel price fluctuations, and increasing demand for last-mile delivery services in 2025, businesses that closely monitor their cost per unit are better positioned to maintain profit margins and customer satisfaction.

Furthermore, cost per unit directly influences freight pricing models, tendering processes, and budgeting forecasts. For third-party logistics providers (3PLs), a clear understanding of this cost helps them accurately quote rates to clients and justify value-added services. For shippers, it highlights areas for potential automation, consolidation, or contract renegotiation. When using cost per unit analysis regularly, businesses can shift from reactive to proactive logistics strategies, ensuring long-term scalability and success in an increasingly dynamic global supply chain.

5 Way to optimize and reduce cost per unit

1. Optimize your logistics strategy

Refining your overall logistics strategy is one of the most effective methods for reducing cost per unit. This begins with assessing the full supply chain, especially first-mile delivery. Businesses can lower transportation expenses and reduce lead times by locating suppliers closer to distribution centers or consolidating shipments. In 2025, strategic sourcing and route optimization tools will become more advanced with AI and machine learning, enabling real-time route planning and freight consolidation.

Furthermore, collaborating with a tech-enabled third-party logistics provider (3PL) like ShipBob or Flexport allows companies to leverage economies of scale, warehouse automation, and predictive analytics. This minimizes fulfillment costs and improves inventory accuracy. An optimized logistics strategy also involves aligning demand forecasting with procurement and distribution to avoid overstocking, which directly affects the unit price.

2. Reduce material costs

Reducing material costs without sacrificing quality is a delicate balance, but remains one of the most effective ways to optimize cost per unit. Businesses can start by renegotiating contracts with suppliers, especially for high-volume SKUs. Beside that, establishing long-term vendor agreements often leads to better pricing, stability, and priority service, particularly important in volatile supply markets. Another practical approach is value engineering—evaluating the design and functionality of a product to reduce raw material usage or switch to more cost-effective alternatives.

In 2025, advancements in sustainable materials and circular supply chains allow logistics professionals to incorporate recyclable or biodegradable packaging, which is both cost-efficient and eco-friendly. Group purchasing organizations (GPOs) also offer small-to-medium enterprises (SMEs) collective buying power to reduce per-unit material expenses.

3. Reduce holding costs

Holding costs—also known as inventory carrying costs—can quietly erode profit margins if not actively managed. These include storage fees, insurance, depreciation, and opportunity costs of capital. To reduce these expenses, businesses should adopt a Just-in-Time (JIT) inventory model or integrate real-time inventory management systems that trigger reorders based on actual demand signals rather than forecasts alone.

In 2025, cloud-based warehouse management systems (WMS) will offer predictive analytics and IoT integration, providing better visibility into stock levels and reducing unnecessary storage. Dynamic slotting and SKU velocity analysis help improve warehouse efficiency by ensuring that high-demand products are stored in easily accessible zones, reducing labor time and space costs. Cross-docking strategies can also significantly minimize storage duration, enabling faster throughput with minimal holding overhead.

4. Reduce dead stock, reshipments, and returns

Deadstock, reshipments, and returns are major contributors to inflated costs per unit. Deadstock ties up capital and warehouse space, while returns and reshipments increase fulfillment costs, customer service burdens, and carbon footprint. To mitigate these issues, accurate demand forecasting is critical. Using AI-powered tools for demand planning helps businesses predict buying trends and seasonal shifts more precisely.

Product information accuracy, robust quality control, and clear sizing guides significantly minimize return rates. Many logistics platforms will integrate with customer feedback systems and e-commerce data to identify patterns in return reasons—allowing companies to proactively fix recurring issues. Implementing reverse logistics programs that facilitate easy returns processing and refurbishment can also recover sunk costs from returned inventory.

5. Eliminate away of unprofitable products

Carrying a wide range of products doesn’t always translate to higher profitability. Unprofitable or slow-moving SKUs often drive up storage, handling, and administrative costs. A regular SKU rationalization audit is essential to identifying which products add value and which diminish the overall margin.

Modern business intelligence tools enable logistics and operations teams to analyze SKU-level profitability across regions and sales channels. Key performance indicators (KPIs) like inventory turnover rate, contribution margin, and gross margin return on inventory investment (GMROII) help flag underperforming products. Phasing out unprofitable SKUs reduces cost per unit and frees up capital and warehouse space for higher-demand items, improving operational agility and cash flow.

Other Unit Cost Metrics You Should Know

Beyond the basic per-unit manufacturing costs, logistics and supply chain professionals should be aware of several other essential unit cost metrics. These indicators provide a clearer picture of operational efficiency and support better pricing, inventory control, and profit forecasting decision-making.

- Cost of Goods Sold (COGS): This refers to the direct expenses of producing goods sold within a given period. In logistics, COGS often includes raw materials, labor, and inbound freight. Monitoring COGS helps determine gross margins and manage supplier relationships effectively.

- Variable Cost per Unit: These costs fluctuate with production volume, such as packaging, handling, or shipping fees. Understanding variable costs enables logistics managers to scale operations flexibly without sacrificing profitability.

- Fixed Cost per Unit: Fixed costs (like warehousing rent or salaried labor) remain constant regardless of output. When spread across more units, the per-unit fixed cost decreases, helping improve cost efficiency in high-volume distribution models.

- Contribution Margin per Unit: This is calculated by subtracting variable costs from the selling price. It’s a vital metric in logistics planning, showing how much each unit contributes to covering fixed costs and generating profit.

- Breakeven Unit Cost: This tells the company how many units must be sold to cover all fixed and variable costs. For logistics firms handling seasonal goods or promotional stock, knowing the breakeven point ensures informed pricing and inventory decisions.

- Inventory Holding Cost per Unit: It includes warehousing, insurance, depreciation, and opportunity costs. Reducing holding costs through just-in-time inventory or warehouse optimization is more critical than ever.

- Shipping and Fulfillment Cost per Unit: It encompasses last-mile delivery, packaging, and fulfillment center operations. With the continued rise of e-commerce in 2025, accurate tracking of fulfillment costs helps maintain competitive pricing without eroding margins.

Cost Per Unit FAQ

What do you mean by cost per unit?

Cost per unit refers to the total expenditure incurred to produce, store, and deliver one individual unit of a product. In the logistics and supply chain context, this includes direct costs such as manufacturing, labor, and raw materials and logistics-related costs like warehousing, freight charges, customs duties, and last-mile delivery expenses.

What is the price per unit cost?

Price per unit cost—often used interchangeably with cost per unit—refers to the amount a company spends per item sold, calculated by dividing total operational costs by the number of units produced or handled. However, in a logistics context, this often emphasizes the cost to transport or fulfill one item through the supply chain, especially in high-volume environments like e-commerce fulfillment or international freight forwarding.

For example, if a logistics provider ships 10,000 units and incurs $50,000 in operational and transport costs, the price per unit would be $5. Monitoring this metric helps logistics firms evaluate the cost-efficiency of routes, carriers, and warehouse strategies in real time.

Cost per unit plays a pivotal role in shaping a company’s financial strategy, influencing everything from pricing models to resource allocation. With the right approach to calculating and optimizing this metric—using clear formulas, accessible calculators, and proven methods—businesses can reduce waste and uncover new opportunities for profitability and scalability.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)