Packing slips play a crucial role in the order fulfillment process, serving as a detailed record of items included in a shipment. This guide provides a comprehensive overview of packing slips, why they’re essential for businesses and customers alike, and how to set them up effectively. Whether you’re managing a small eCommerce shop or a large-scale warehouse, understanding how to use packing slips can streamline operations and reduce shipping errors.

What is Packing Slip?

A packing slip, also known as a packing list or delivery docket, is a crucial document in logistics that accompanies a shipment of goods. It provides a detailed summary of the items included in a delivery, ensuring accuracy and transparency between the shipper, carrier, and recipient. Unlike an invoice, a packing slip typically does not include pricing information—it focuses purely on what is being shipped.

Packing slips are vital in order fulfillment, helping warehouse teams verify that all ordered items are picked, packed, and shipped correctly. For the consignee, they serve as a checklist to cross-reference the delivered goods against the original purchase order. In larger supply chains, packing slips assist with inventory reconciliation and return processing and serve as proof of shipment discrepancies or damages.

Purpose of a Packing Slip

Shipment integrity

A packing slip acts as a physical verification document used during the picking, packing, and dispatching stages of order fulfillment. Warehouse personnel rely on the packing slip to ensure that the contents of a shipment align with the purchase order or sales invoice. Also, the packing slip minimizes discrepancies and reduces the risk of errors during transit by providing a clear breakdown of SKU numbers, quantities, and product descriptions.

Ability to divide orders

Packing slips also facilitate the division of orders across multiple shipments, which is especially valuable in logistics operations involving split shipments or backorders. When inventory is spread across various distribution centers or when certain items are temporarily out of stock, businesses may need to fulfill a single customer order in parts. A well-prepared packing slip for each parcel helps clarify what items are included in each shipment and which are pending.

This is crucial for inventory management systems and order tracking. Segmenting the order while maintaining transparency reduces customer confusion and enhances supply chain efficiency. Additionally, the packing slip helps customer service teams handle inquiries more effectively by referencing which items were dispatched and when.

Customer satisfaction

When customers receive a detailed packing slip alongside their shipment, they gain confidence in the transaction. It provides a tangible confirmation of what was ordered versus what was delivered, thereby reducing the likelihood of claims or returns due to misunderstandings.

Key Information on a Packing Slip

For businesses engaged in inventory management and order processing, understanding the key elements of a packing slip is essential to maintaining operational efficiency and customer satisfaction.

Shipping information

Shipping information is one of the most critical sections on a packing slip. It includes details such as the recipient’s name, full delivery address, shipping method (e.g., ground, express, air freight), and the shipping date.

This data ensures the package is routed correctly and delivered within the expected timeframe. This section is frequently cross-referenced in logistics workflows with the shipping label and the carrier’s tracking system to monitor delivery status and resolve transit issues efficiently.

List of items

The list of items section provides a detailed breakdown of all products included in the shipment. Each line item typically consists of the product name, SKU (stock keeping unit), quantity shipped, and occasionally the unit price or product description.

This allows warehouse teams to confirm accuracy during packing and receiving, and helps the recipient verify that the correct items have been delivered. Including this list also aids in dispute resolution in case of discrepancies between what was ordered and what was received.

Missing items

This section prevents confusion for the customer and provides an audit trail for follow-up logistics actions. Clear labeling such as “To be shipped separately” or “Out of stock – shipping later” is often used. Including this information ensures the recipient does not mistakenly report missing items as lost or incorrectly fulfilled.

Inventory number

An inventory number is a unique identifier that businesses assign to individual products within their inventory management system. This number helps shippers and recipients track and verify items accurately on a packing slip. Standard formats include Stock Keeping Units (SKUs) and Universal Product Codes (UPCs), which are frequently used to streamline warehouse operations.

In practice, inventory numbers are essential for locating products in a storage facility and are often tied to inventory software for quick access. If an issue arises, such as a missing or damaged item, the customer can refer to the inventory number on the packing slip, allowing the seller to trace and resolve the problem swiftly. This system improves inventory accuracy, enhances order traceability, and supports efficient customer service.

Slip number

The slip number is a unique code assigned to a packing slip, helping businesses track and manage individual shipments, especially when an order is split across multiple packages. This identifier links each package to the same customer order, ensuring all items are correctly grouped during shipping and delivery.

For example, if a single order is divided into several boxes, each box will include a packing slip with the same slip number. This helps logistics staff and recipients verify that all parts of the order belong together. The slip number also plays a key role in internal systems such as warehouse or order management software, supporting accurate tracking, smoother communication, and quicker resolution of shipping-related issues.

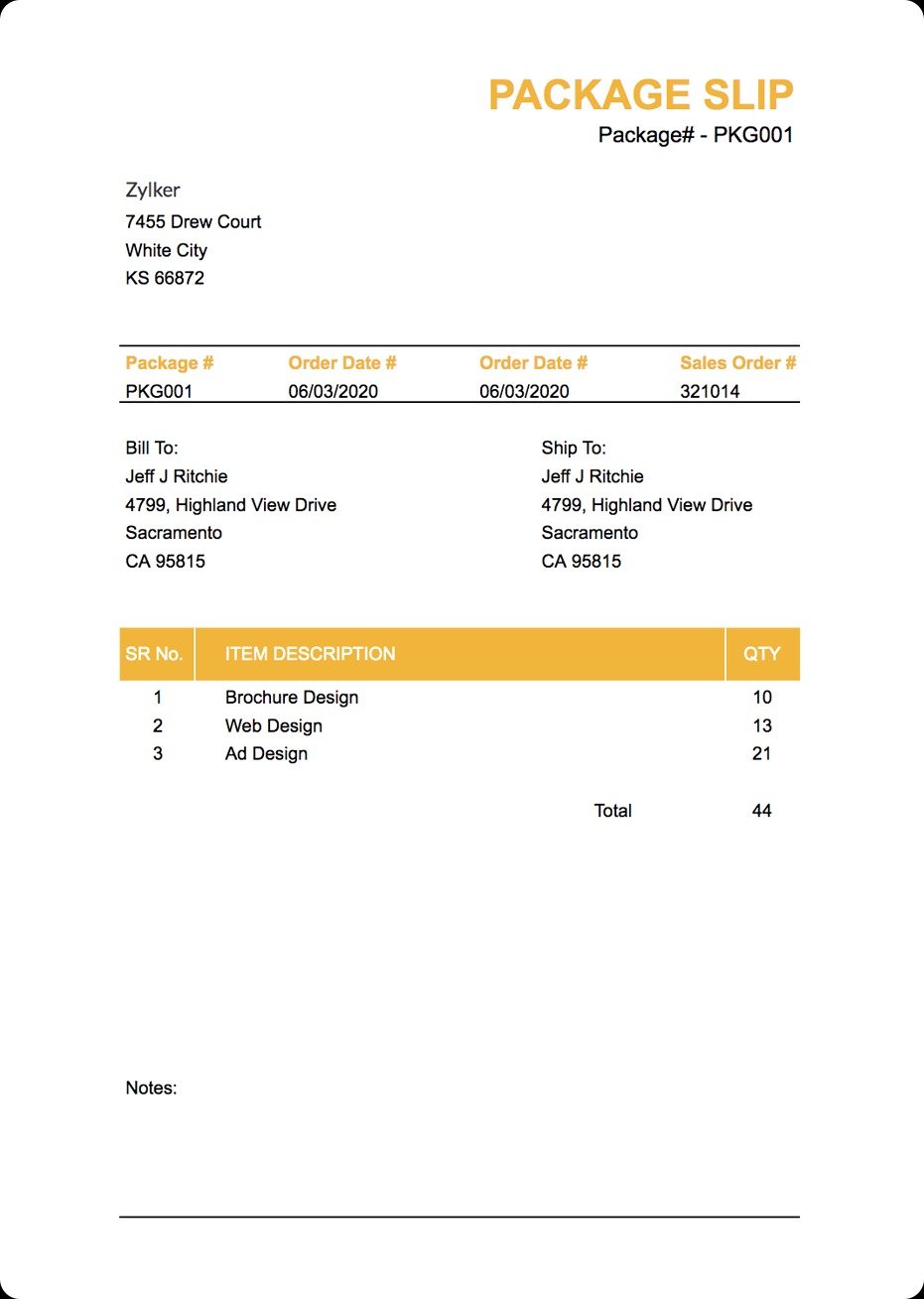

Example of Packing Slip

Below is a sample packing slip used in logistics. It includes key details like package number, order date, shipping and billing addresses, and a list of items with quantities. This helps ensure accurate delivery and smooth record-keeping between parties.

The differences between packing slips and invoices, shipping labels, delivery notes?

Four commonly used documents: packing slips, invoices, shipping labels, and delivery notes, serve distinct purposes. Understanding their differences is crucial for warehouse staff, shippers, and customers alike to avoid confusion, ensure compliance, and maintain operational accuracy.

Below is a comparison table that highlights the key distinctions among these documents:

| Feature | Packing Slip | Invoice | Shipping Label | Delivery Note (often Proof of Delivery – POD) |

| Primary Purpose | To itemize the physical contents of a specific package or pallet for verification by the recipient. | A commercial document issued by a seller to a buyer, requesting payment for goods sold or services provided. | To provide all necessary information for a carrier to transport a shipment from its origin to its destination. | To provide evidence that a consignment was delivered to the intended recipient and confirm the state of the goods. |

| Key Information Included | A detailed list of items within the shipment (SKUs, descriptions, quantities shipped), and the order number. Typically, this list excludes pricing. | Itemized list of goods/services, unit prices, total amount due, payment terms, tax details, invoice number, consignor and consignee financial details. | The information includes the addresses of the consignor (shipper) and Consignee (recipient), the tracking number, carrier information/service type, barcodes for sortation, and often weight/dimensions. | List of goods delivered, quantities, date and time of delivery, name and signature of the recipient, any remarks on damage or shortages. |

| Who Primarily Uses It? | Recipient (for checking received goods against the order), Warehouse staff (for picking and packing accuracy). | Buyer’s Accounts Payable department (for payment), Seller’s Accounts Receivable department (for collections), and Customs (for international shipments). | Carrier personnel (drivers, sorters), automated sortation systems, dispatch teams, and recipients (for tracking status) are also needed. | Consignee (to acknowledge receipt), Carrier (as Proof of Delivery), Consignor (for delivery confirmation and dispute resolution). |

| When Is It Generated/Used? | Generated during order fulfillment; typically included inside the package with the goods. Used by the recipient upon delivery. | Generated after an order is placed or goods are shipped; often sent separately (email/post) to the buyer. Used for payment processing and accounting. | Generated when the shipment is prepared for dispatch by the carrier; affixed securely to the package’s exterior. Used throughout the transit process. | It often travels with the goods or is presented by the carrier at the point of delivery. It is signed by the recipient, and a copy is retained by the carrier and returned to the shipper. |

| Contains Financial Data (Pricing)? | No | Yes (its primary function involves financial details) | No | No (typically, its focus is on acknowledgment of receipt, not value) |

Best guide packing slips to practices

Using automated tools and software

Using automated systems to create packing slips minimizes human error, streamlines order fulfillment, and allows seamless integration with inventory management systems (IMS), warehouse management systems (WMS), and enterprise resource planning (ERP) platforms. When orders are processed, packing slips can be automatically generated with accurate SKU details, item quantities, shipping addresses, and order references.

Companies using platforms like ShipStation, NetSuite, or Zoho Inventory benefit from customizable packing slip templates that can be aligned with operational needs. These tools ensure real-time data synchronization, reduce delays during pick-and-pack operations, and enhance traceability. For high-volume shippers, automation also enables batch printing of packing slips, supporting bulk order dispatching without sacrificing accuracy.

Maintaining environmental considerations

Many companies are moving toward eco-friendly printing practices, such as using recycled paper and soy-based inks or integrating packing slips digitally via QR codes to minimize waste. These actions support corporate social responsibility goals while reducing the environmental footprint of day-to-day operations.

Logistics providers can also opt for paperless packing slips, especially in B2B transactions where digital documentation is accepted. This reduces paper consumption and cuts down on printing costs and storage needs.

Tips for enhancing brand presentation

A well-designed packing slip that includes brand logos, personalized thank-you notes, or contact information helps reinforce brand presence and improves the customer’s unboxing experience. This is especially important in e-commerce, where packaging is often the first physical interaction between the customer and the brand.

Here are some tips you can follow:

- Use consistent brand colors and typography.

- Add a small section with customer service contact details or return instructions.

- Ensure the layout is clean, easy to read, and matches the tone of your brand.

Packing Slip FAQ

How to print a packing slip

To print a packing slip, you typically need to locate the order or transaction, access a “Print” or “Packing Slip” option within your system (e.g., e-commerce platform, accounting software), and then print the generated PDF.

How to look for a multi-carrier shipping platform?

When selecting a multi-carrier shipping platform, logistics managers should evaluate key features such as carrier integration, rate comparison tools, real-time tracking, and automation capabilities. They should also consider scalability, ease of integration with existing ERP or eCommerce platforms (like Shopify or Magento), and customer support responsiveness. Finally, they must look for platforms that offer analytics dashboards to monitor performance metrics like delivery times, shipping costs, and carrier reliability.

How are packing slips important for ecommerce businesses?

Packing slips play a vital role in eCommerce logistics by providing a clear summary of order contents for both the shipper and recipient. They help prevent shipping errors, support smooth returns processing, and provide transparency that builds customer trust. In warehouse environments, they act as a checklist for pick-and-pack staff, minimizing the chance of incorrect items being sent.

For international shipping, packing slips may also assist in customs documentation when paired with invoices. In a competitive eCommerce landscape, including an accurate and professional packing slip can enhance the post-purchase experience and reinforce brand reliability.

In conclusion, packing slips are essential tools for ensuring smooth and accurate order fulfillment. By understanding their purpose, learning how to use them effectively, and setting them up with the right details, businesses can streamline operations and enhance customer satisfaction. A well-implemented packing slip process ultimately supports better inventory management and professional order handling.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)