Reverse logistics is the opposite of the usual supply chain flow, moving goods from consumers back to manufacturers. It covers tasks like returns management, refurbishment, recycling, and disposal. This process addresses product returns caused by damage, seasonal stock, restocking, salvage, recalls, or excess inventory. This blog explores its definition, processes, benefits, and rising importance across industries.

What is reverse logistics?

Reverse logistics is a crucial component of supply chain management that focuses on the movement of products, materials, and information in the opposite direction of traditional logistics—from the point of consumption back to the point of origin. Unlike forward logistics, which handles the delivery of goods from manufacturers to consumers, reverse logistics involves processes such as returns management, recycling, repairs, remanufacturing, and proper disposal.

In today’s competitive market, companies use reverse logistics to recover value from returned goods, minimize waste, and improve customer satisfaction. By effectively managing returns, companies can reduce costs, comply with environmental regulations, and maintain brand reputation. Key activities within reverse logistics include product recalls, warranty repairs, refurbishing, and sustainable disposal of goods.

Reverse Logistics Process: How It Work?

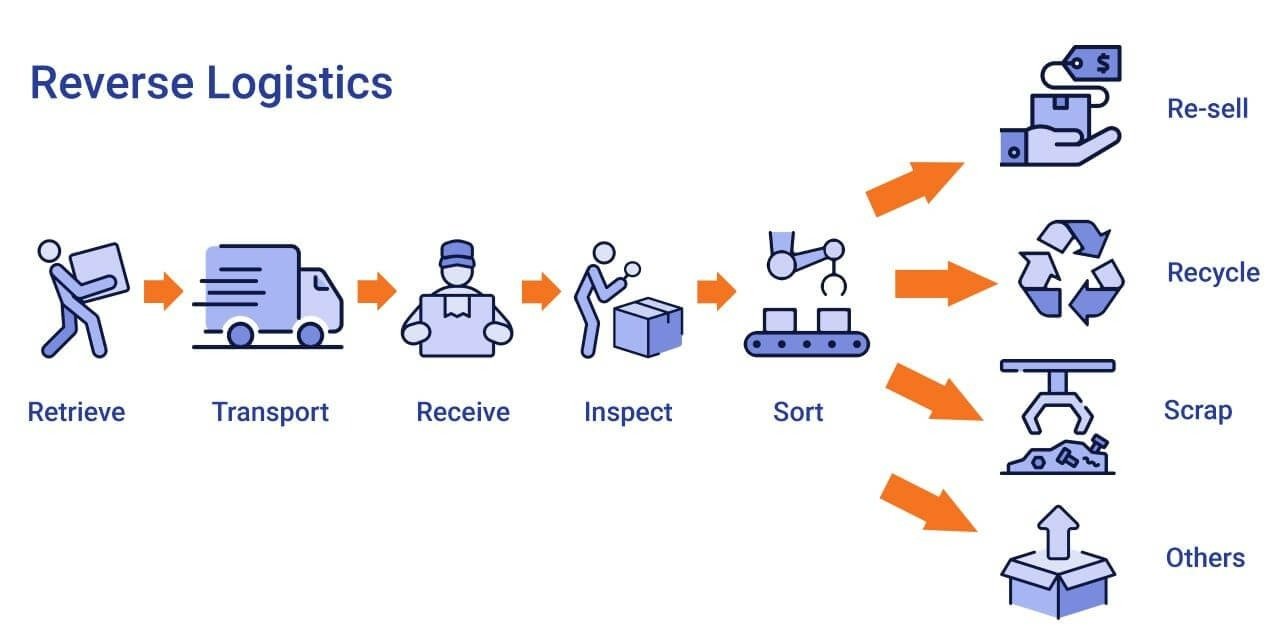

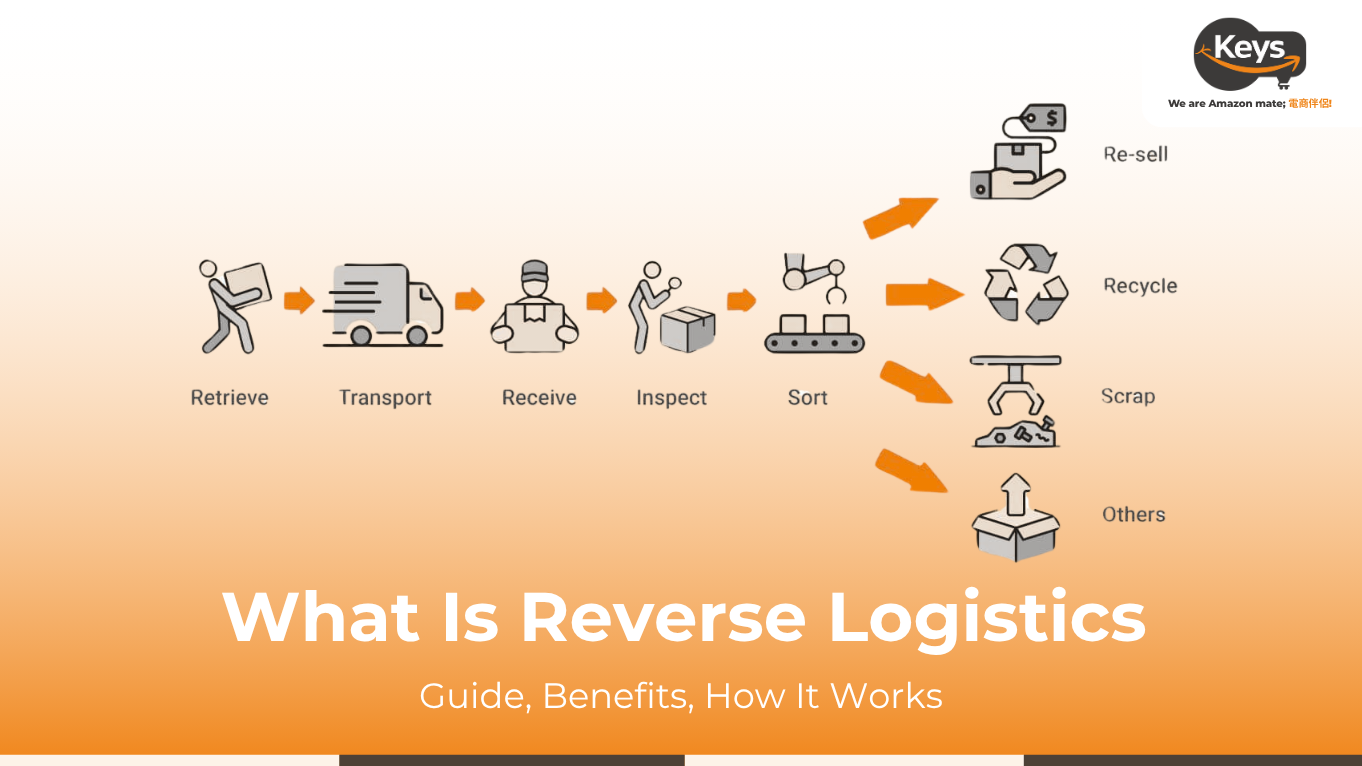

Reverse logistics plays a crucial role in today’s supply chains, helping companies manage product returns, repairs, recycling, and the sustainable disposal of goods. Here’s how reverse logistics typically works:

Step 1: Product Returns Initiation

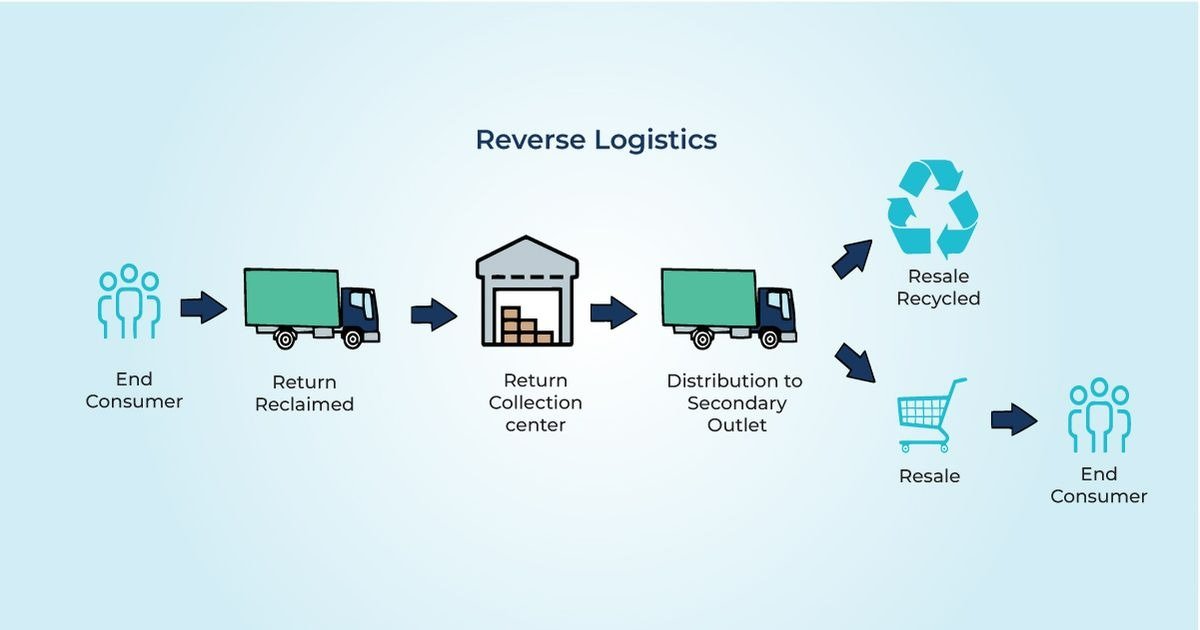

The reverse logistics process starts when a customer initiates a return, requests a repair, or chooses to recycle a product. This action triggers the return journey of the item from the point of consumption back to the seller’s facility or an authorized service center. During this step, logistics teams coordinate the safe and timely transport of the item to avoid further damage or loss. Clear communication with customers about return procedures helps ensure smooth handling and sets the stage for efficient processing.

Step 2: Inspection and Sorting

Once the product arrives at the designated facility, it undergoes a comprehensive inspection to assess its condition and determine the next steps. This inspection identifies issues such as damage, defects, or wear. Based on the findings, products are sorted into categories:

- Reusable: Items that can be restocked or resold.

- Repairable: Products that can be fixed or refurbished.

- Recyclable: Items that can be broken down to recover valuable materials.

- Waste: Goods that must be responsibly discarded.

This classification is critical for streamlined processing and effective resource management.

Step 3: Processing and Disposition

After sorting, the appropriate action is taken for each category. Repairable items are repaired or refurbished to restore them to working condition, ready for resale or reuse. Recyclable products are sent to material recovery centers to extract valuable components such as metals, plastics, or electronics. Items that cannot be reused or recycled are disposed of in compliance with environmental regulations, ensuring minimal ecological impact.

Step 4: Reintegration or Disposal

The final step focuses on reintegrating usable products into the company’s inventory or production cycle. This helps recapture value and reduces the need to manufacture new products, thereby saving costs and resources. For items in good condition, resellers often sell them at discounted prices through secondary markets. Products that cannot be recovered are responsibly disposed of, completing the reverse logistics cycle and maintaining a sustainable, circular economy.

9 Types of reverse logistics

Reverse logistics encompasses various activities that help businesses manage product returns, recycling, repairs, and asset recovery efficiently. Here are nine key types of reverse logistics every logistics manager should understand:

- Returns management: Returns management involves handling product returns from customers in a fast, visible, and controllable way. Efficient returns processes are critical because customers judge a company based on its returns experience. A key challenge is managing returns, where a product is returned a second time, often triggering extended return policies or store credit. For example, a customer may buy a clearance item, discover it is faulty, and seek a return, even when standard policies don’t allow it.

- Return policy and procedure: A company’s return policy and procedure (RPP) outlines how customers can return items and what conditions apply. Consistent, visible policies help manage expectations and protect the company’s brand. Employees must be trained to follow these guidelines, ensuring that all returns are handled fairly and consistently.

- Remanufacturing or refurbishment: This process involves repairing, rebuilding, or reworking products to restore their functionality. Companies often recover interchangeable parts or materials from other products—a practice known as cannibalization of parts. Reconditioning may include disassembling, cleaning, and reassembling products to give them a second life.

- Packaging management: Packaging management focuses on reusing or recycling packaging materials to reduce waste and disposal costs. By implementing efficient reverse logistics packaging, companies can reduce their environmental footprint and improve overall sustainability.

- Unsold goods: Reverse logistics for unsold goods manage returns from retailers back to manufacturers or distributors. Reasons for these returns include poor sales, inventory obsolescence, or delivery refusals.

- End of service life: When a product reaches its end of life (EOL)—whether due to obsolescence, wear, or replacement by a newer version—manufacturers often recycle or dispose of it. This step is critical for environmental compliance and resource recovery.

- Delivery failure: Delivery failure occurs when goods cannot be delivered to the customer and are returned to the sorting center or point of origin. Some sorting centers can identify delivery issues, correct them, and attempt redelivery, ensuring customer satisfaction while minimizing costs.

- Rental equipment: When equipment reaches the end of a lease or rental agreement, companies handle its return through reverse logistics. Options include remarketing, recycling, or redeployment.

- Repair and maintenance: When equipment reaches the end of a lease or rental agreement, companies handle its return through reverse logistics. Options include remarketing, recycling, or redeployment.

Benefits of Reverse Logistics for Ecommerce Businesses

Implementing a robust reverse logistics process provides ecommerce businesses with a strategic advantage in today’s competitive marketplace. Here are the key benefits of adopting reverse logistics:

- Improved Customer Satisfaction: A seamless and efficient returns process is crucial for e-commerce businesses aiming to build long-term customer loyalty. When customers can easily return products and receive quick refunds or exchanges, their trust in the brand grows.

- Enhanced Brand Reputation: A well-managed reverse logistics system demonstrates a commitment to customer care and service excellence, which resonates with consumers who value reliable and hassle-free shopping experiences.

- Reduced Costs and Increased Profitability: Reverse logistics enables businesses to efficiently manage returns, repairs, and refurbishments, helping them reduce unnecessary transportation and warehousing costs. By refurbishing and reselling returned items, companies can create new revenue streams that offset potential losses from returns.

- Greater Sustainability: Reverse logistics plays a key role in supporting sustainable business practices. By recycling or reusing returned products and packaging, companies minimize landfill waste and reduce their carbon footprint. This alignment with green initiatives not only meets regulatory requirements but also appeals to environmentally conscious consumers who prefer brands committed to environmental responsibility.

Challenges of Reverse Logistics

One of the most significant challenges is establishing the right logistics infrastructure to support reverse flows. This typically involves investing in:

- Warehouse Management Systems (WMS) or Enterprise Resource Planning (ERP) systems that handle returns, repairs, recycling, and disposal.

- Real-time visibility tools for tracking the location and status of returned products.

- Automated workflows to minimize manual handling and reduce errors.

Moreover, implementing the infrastructure is just the beginning. Companies need to:

- Continuously monitor and evaluate reverse logistics processes to ensure they remain efficient and cost-effective.

- Track and analyze key performance indicators (KPIs) to identify bottlenecks and opportunities for improvement.

- Adapt processes to customer needs and changing regulations to maintain compliance and satisfaction.

Another challenge is the need to coordinate inbound and outbound logistics alongside reverse logistics. While inbound logistics manages the receipt of raw materials or goods from suppliers to manufacturers, and outbound logistics oversees the delivery of finished goods to customers, reverse logistics can start at any point in the supply chain. Companies must integrate all these flows to get a complete picture of their supply chain performance.

Strategies to Optimize Reverse Logistics

To optimize reverse logistics, companies need to implement a cohesive strategy that prioritizes speed, efficiency, and cost-effectiveness. Below are seven essential strategies for improving reverse logistics operations:

- Evaluate Relevant Policies and Agreements: Companies should begin by reviewing and updating policies related to returns and repairs. These procedures must be clear, transparent, and aligned with customer expectations. Understanding the root causes of returns, such as product quality or shipping damage, can help companies adjust sales and manufacturing processes to reduce return rates.

- Collaborate with Suppliers: Building strong relationships with suppliers helps align processes, minimize delays, and improve product quality and service levels. A coordinated approach between suppliers and logistics providers ensures that customers have a seamless experience, which can lead to greater brand loyalty.

- Use Data to Optimize Processes: Collecting and analyzing data on product returns can gain insights into why products are returned, such as quality issues, shipping damage, or incorrect orders. These insights allow businesses to make targeted improvements to sales practices, product design, and forward logistics processes.

- Track Products Forward and Backward: Tracking products both forward and backward ensures that in the event of recalls, companies can quickly identify and isolate affected items instead of recalling entire product lines. This capability improves customer safety while reducing unnecessary costs and disruptions.

- Centralize Return Centers: Establishing a centralized return center, companies can more effectively evaluate each item’s condition and determine whether it should be repaired, refurbished, resold, recycled, or disposed of. For companies with limited resources, dedicating a portion of an existing warehouse or factory to returns can still yield significant improvements in efficiency and cost savings.

- Examine Logistics and Transportation: Companies should look for opportunities to integrate processes, such as having delivery drivers pick up empty pallets or returns during deliveries. This approach reduces trips, saves fuel, and maximizes truck utilization—ultimately lowering costs and enhancing sustainability.

- Automate Operations: Implementing cloud-based logistics software enables real-time tracking of returned goods, management of refurbishment processes, and analytics that provide valuable business insights. By digitizing reverse logistics processes, companies can reduce manual workloads, improve accuracy, and respond more quickly to customer needs.

Reverse Logistics FAQ

Forward Logistics vs Reverse Logistics

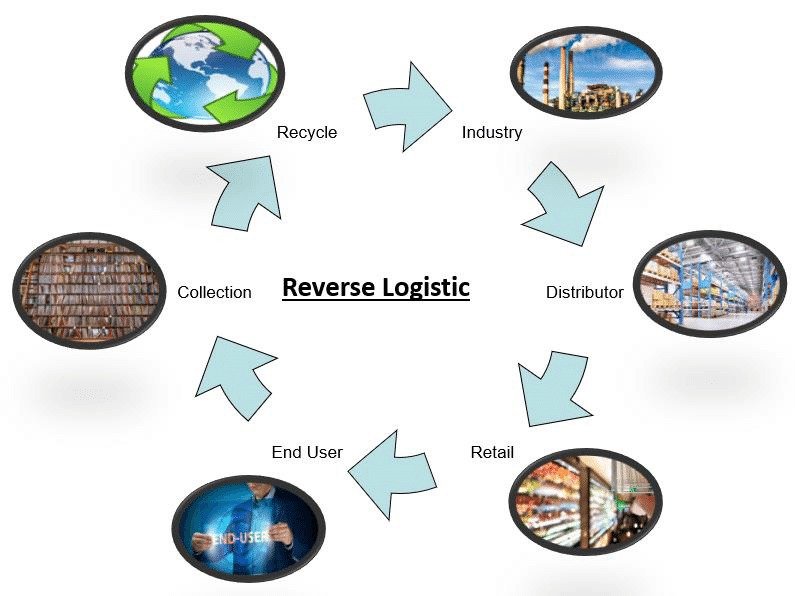

Forward logistics refers to the traditional flow of goods, starting with raw materials at the manufacturer and moving through distributors and retailers before finally reaching the end customer. This process is typically linear and straightforward, focused on getting products into the hands of consumers as efficiently as possible.

In contrast, reverse logistics is the backward movement of goods, often initiated by the consumer. This process involves returning defective products, managing product recalls, recycling, refurbishing, or safely disposing of items. Reverse logistics covers everything that happens after the consumer decides to return an item, including planning and implementing strategies to reduce the costs and losses associated with returns while improving the overall returns experience. Effective reverse logistics helps businesses recapture value, minimize waste, and enhance customer satisfaction.

Reverse Logistics vs. Traditional Logistics

Traditional logistics follows a predictable, forward-moving path that starts with suppliers, moves through manufacturing or distribution centers, and ends at retail stores or directly with consumers. This supply chain design focuses on efficiently delivering products from the point of production to the point of sale.

On the other hand, reverse logistics begins at the customer and moves in the opposite direction, returning products to any point along the supply chain. This can include routing returned goods back to a distributor, a repair facility, or even the original manufacturer. Well-designed supply chains incorporate reverse logistics capabilities to handle returns, manage product recalls, or reroute items into secondary markets like discount outlets or liquidators. This flexibility is essential for modern supply chains to respond effectively to product returns, damaged goods, and changing customer demands.

Reverse logistics goes beyond simply managing product returns; it’s a strategic approach that helps companies reduce costs, improve sustainability, and enhance customer experiences. By embracing reverse logistics software and investing in AI-powered last-mile logistics solutions, businesses can transform their supply chains into competitive assets. Prioritizing reverse logistics is essential for companies aiming to stay ahead in a dynamic market.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)