Sustainable Warehousing is transforming modern logistics by reducing environmental impact while improving long-term efficiency. It involves eco-friendly infrastructure, energy optimization, and responsible supply chain practices. In an era of increasing ESG requirements and rising operating costs, building a sustainable warehouse strategy is no longer optional – it’s essential. This article explores what Sustainable Warehousing means, why it matters, and how your business can adopt it effectively.

What is Sustainable Warehousing?

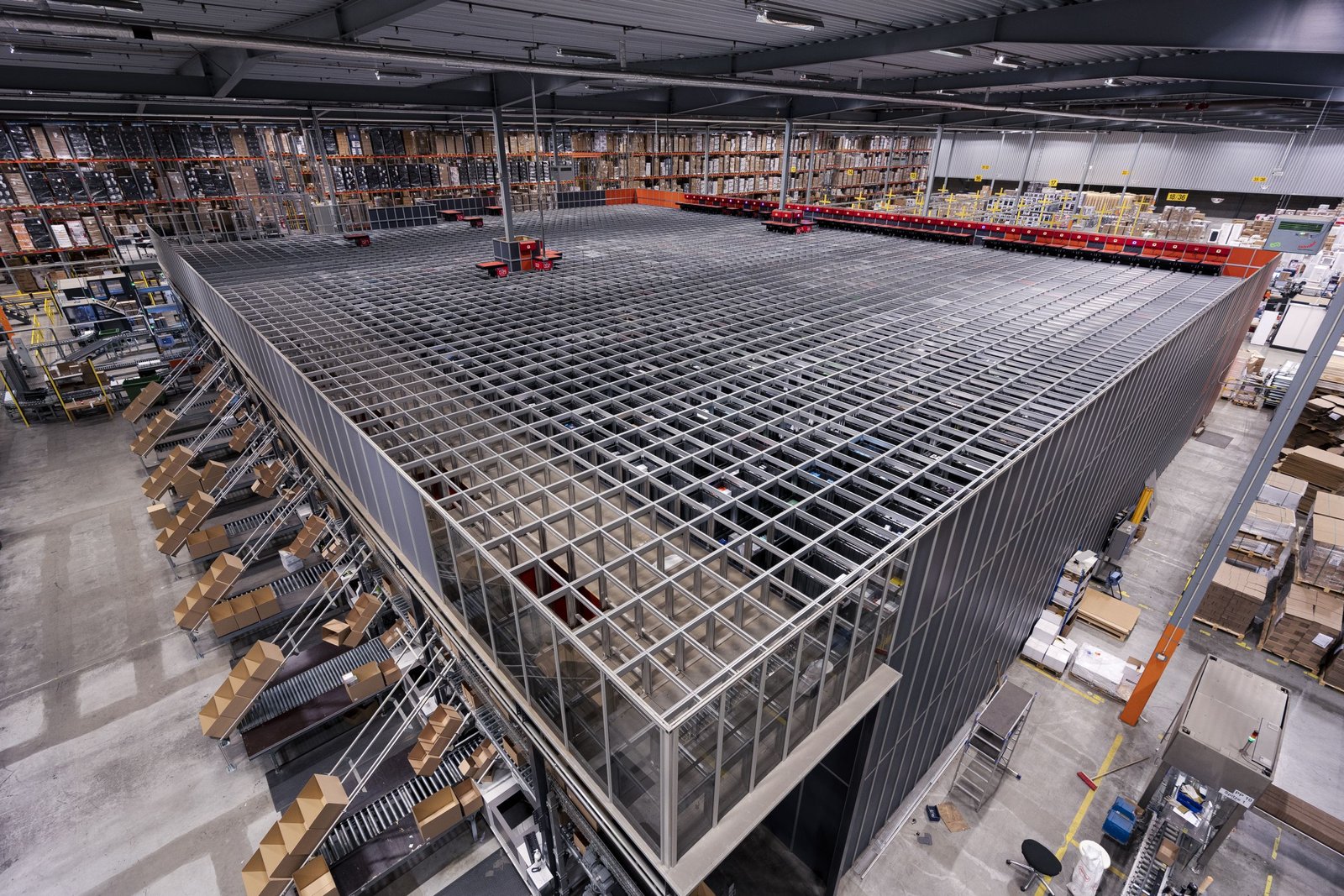

Sustainable warehousing refers to the practice of operating storage and distribution facilities in ways that minimize environmental impact, improve energy efficiency, and promote long-term operational resilience. This approach integrates eco-friendly building materials, renewable energy sources, and smart inventory systems to reduce waste and carbon emissions.

It also emphasizes responsible labor practices and the circular use of packaging and equipment. As consumer demand and regulatory pressure for greener supply chains increase, sustainable warehousing becomes not just a trend but a strategic advantage in modern logistics.

Why is Sustainable Warehousing Important?

Sustainable warehousing is important because it addresses the growing need for environmentally responsible logistics in a world facing climate change and resource depletion. As global supply chains expand, warehouses consume more energy, generate more waste, and contribute significantly to carbon emissions.

Transitioning to sustainable practices helps businesses comply with environmental regulations, meet stakeholder expectations, and align with ESG (Environmental, Social, and Governance) goals. More than a competitive edge, it reflects corporate accountability and future-proofing in an economy where customers, investors, and governments increasingly prioritize sustainability.

Benefits of Implementing Sustainable Warehousing

From operational efficiency to long-term risk reduction, Sustainable Warehousing provides a strategic edge that aligns with both economic and ethical goals. Below are key benefits companies can expect when making this shift:

Cost Savings

One of the most immediate benefits of Sustainable Warehousing is cost reduction. Energy-efficient lighting, automated climate control, and solar power integration can drastically lower utility bills. Using recyclable or reusable packaging materials reduces purchasing costs over time. Additionally, optimized storage layouts and smart inventory systems minimize waste and improve throughput. Though initial investments may seem high, sustainable upgrades often yield significant returns through reduced operational expenses and resource optimization.

Regulatory Compliance

As governments introduce stricter environmental regulations, companies with sustainable warehouses are better positioned to meet compliance requirements. From emissions standards to waste management protocols, aligning with green policies helps avoid fines, delays, and legal liabilities. Sustainable Warehousing also simplifies the audit process, thanks to improved documentation and transparent systems. Being proactive with compliance not only protects operations but builds resilience against evolving global standards.

Brand Reputation

In an era where consumers and investors value transparency and responsibility, sustainability enhances brand perception. Warehouses that operate sustainably contribute to a company’s broader ESG narrative, reinforcing trust and loyalty. By adopting Sustainable Warehousing practices, businesses demonstrate commitment beyond profit – supporting ethical supply chains and environmental stewardship. This positions the brand as forward-thinking and socially conscious, which can influence customer choice and investor confidence.

Employee Satisfaction and Safety

Sustainability efforts often improve working conditions within the warehouse. Better ventilation, natural lighting, and reduced noise pollution contribute to a healthier, more comfortable environment. Additionally, eco-friendly design usually incorporates safer materials and ergonomic layouts that minimize injury risks. Employees who feel valued and safe tend to be more engaged, productive, and loyal. Thus, Sustainable Warehousing supports not only environmental goals but also workforce well-being – a win-win for long-term operational success.

Challenges in Adopting Sustainable Warehousing

While the benefits of Sustainable Warehousing are clear, transitioning to greener operations isn’t without its hurdles. Businesses often face practical, financial, and operational barriers when shifting from traditional models to environmentally responsible warehousing. Understanding these challenges is key to developing realistic implementation strategies.

High Initial Investment

One of the biggest obstacles to Sustainable Warehousing is the upfront cost. Installing solar panels, upgrading insulation, purchasing energy-efficient equipment, or redesigning facility layouts can require significant capital. For small and mid-sized businesses, this investment may not be feasible without external funding or long-term planning. Even though these improvements reduce operational costs over time, the delayed return on investment can discourage early adoption – especially in industries with tight margins.

Technological Integration

Sustainability often requires digital transformation. From energy monitoring systems to AI-driven inventory management, Sustainable Warehousing depends on integrated technologies. However, many warehouses still rely on outdated infrastructure or siloed data systems. Migrating to new platforms can be complex and disruptive if not managed properly. The challenge lies in aligning green initiatives with scalable, user-friendly tech that works across departments without compromising performance or security.

Training and Adaptation

Implementing sustainable practices demands a cultural shift within the workforce. Employees must learn new systems, adopt new habits, and sometimes change the way they approach routine tasks. Without proper training and ongoing support, resistance to change can slow down or even derail Sustainable Warehousing initiatives. Managers must invest in skill development and internal communication to foster understanding and buy-in across all roles – from warehouse staff to logistics planners.

How to Build and Enhance Sustainable Warehousing

Building and enhancing Sustainable Warehousing requires a strategic blend of facility design, process optimization, and technological integration. Whether you’re constructing a new distribution center or retrofitting an existing site, every decision should align with environmental performance goals and supply chain efficiency.

Here’s how to build a future-ready warehouse:

- Design with sustainability in mind: Incorporate eco-certified construction materials, install energy-efficient HVAC systems, and leverage renewable energy sources such as solar panels and wind turbines to minimize carbon footprint.

Automate operations for efficiency: Implement advanced Warehouse Management Systems (WMS), Automated Guided Vehicles (AGVs), and Internet of Things (IoT) sensors to streamline inventory movement, reduce idle time, and optimize energy usage. - Adopt green packaging solutions: Switch to recyclable, biodegradable, or reusable packaging materials to reduce landfill waste and lower packaging-related emissions.

- Foster a sustainability-focused workforce: Conduct regular training programs on energy conservation, lean warehousing principles, and environmental compliance. Encourage staff engagement through green KPIs and performance incentives.

- Track and optimize environmental metrics: Continuously monitor key indicators such as kilowatt-hour consumption, water usage, emissions, and waste generation to identify areas for improvement and validate your ESG (Environmental, Social, Governance) goals.

Tips to optimize Sustainable Warehousing

To maintain long-term performance and meet evolving environmental standards, Sustainable Warehousing requires more than initial investment – it demands consistent optimization. By embedding sustainability into every layer of warehouse operations, businesses can achieve both ecological and economic resilience.

Regular Audits and Upgrades

Periodic sustainability audits are essential for identifying inefficiencies in energy use, equipment performance, and waste management. Facilities should benchmark current operations against industry best practices and regulatory requirements. Upgrading to LED lighting, smart climate control systems, and energy-efficient conveyors helps reduce emissions and operating costs. These upgrades also extend the warehouse’s life cycle while aligning with environmental KPIs. A proactive maintenance plan further ensures machinery runs at peak efficiency, minimizing energy waste and unplanned downtime.

Supplier Collaboration

Sustainable Warehousing extends beyond the four walls of a facility—it begins with a green supply chain. Collaborating with eco-conscious suppliers helps reduce carbon emissions from inbound logistics and packaging materials. Encourage vendors to adopt sustainable sourcing, recyclable packaging, and consolidated deliveries. Creating shared sustainability goals and performance benchmarks fosters transparency and mutual accountability. Strong supplier alignment not only reduces environmental impact but also strengthens relationships and improves overall logistics synergy.

Continuous Improvement and Innovation

Adopting a culture of continuous improvement is key to optimizing Sustainable Warehousing. Encourage cross-functional teams to identify and implement low-impact solutions, such as lean warehousing techniques or AI-driven inventory forecasting. Innovation in material handling, like drone inventory checks or autonomous mobile robots (AMRs), enhances efficiency while lowering energy consumption. By regularly piloting and scaling new technologies, warehouses stay ahead of compliance standards and market expectations – driving competitive advantage through sustainable innovation.

Sustainable Warehousing is more than a trend—it’s a strategic shift toward future-proof logistics. From minimizing waste to enhancing operational agility, its benefits span cost savings, compliance, and customer trust. By embracing continuous innovation and collaboration across the supply chain, your warehouse can deliver high performance with a lower footprint. Start today to position your business at the forefront of green logistics.

Ready to upgrade your supply chain with flexible, tech-driven logistics? Keys Logistics offers multimodal transportation, global partnerships, real-time tracking, and dedicated fleet services tailored to your business needs. Whether you’re scaling operations or optimizing fulfillment, we provide the infrastructure and expertise to move your goods reliably and efficiently. Contact us today to streamline your shipping and fulfillment strategy with a trusted logistics partner.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)